Efficiency

Availability

Brand Reputation

Devices

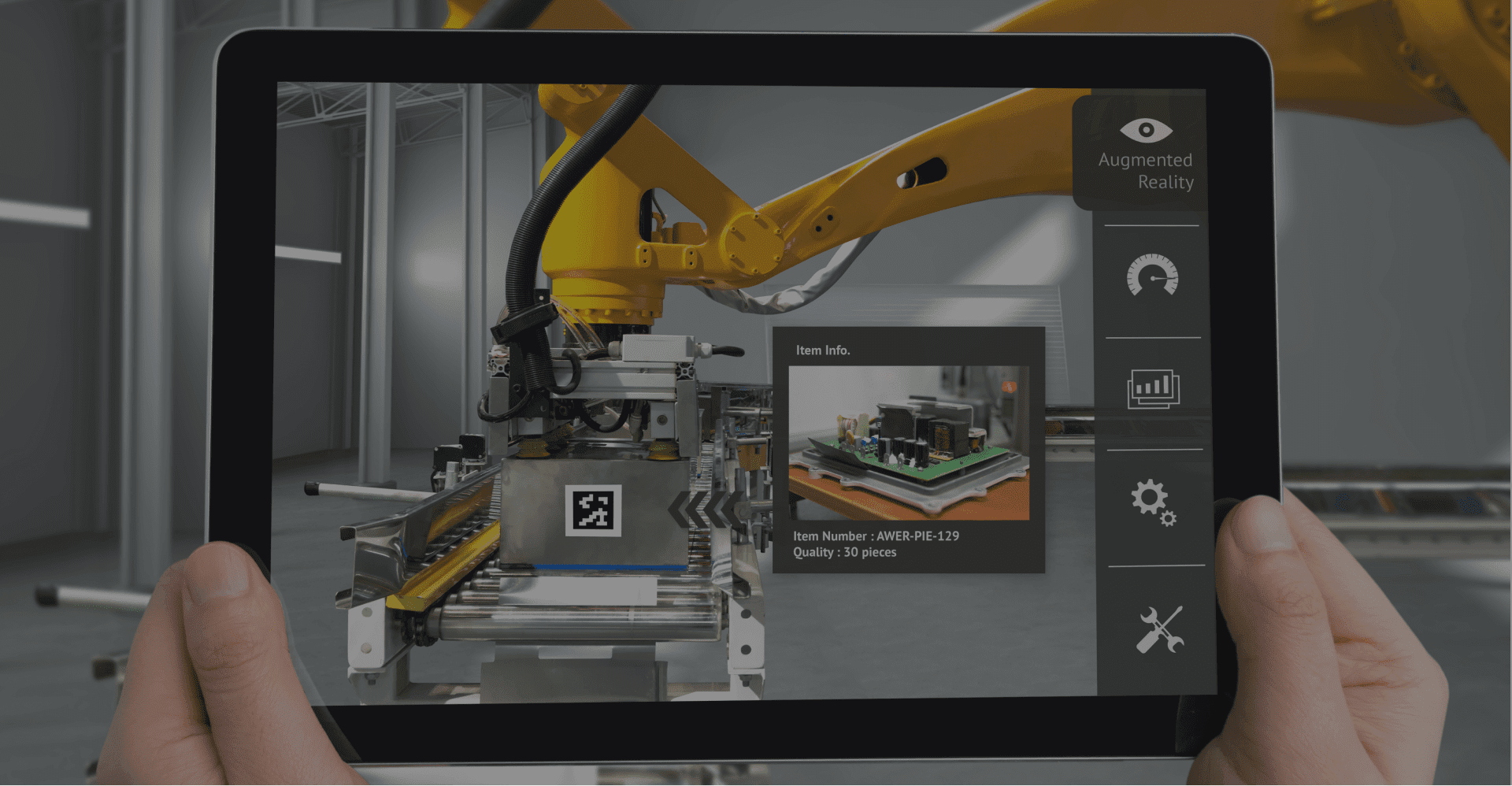

In the hyperconnected Industry 4.0, IoT is no longer a futuristic, nice-to-have optional extra. Today, IIoT enabled, unified communication devices, that are standard in FactoryWorxTM MES, form an essential survival toolkit for modern manufacturing. Through predictive analytics Industry 4.0 devices enable informed, live-or-die business decisions that add value to your business and throughout the value chain.

FactoryWorxTM

Industry 4.0 DEMO ENQUIRY FORM

Starting with automation or looking for a holistic MES Solution? Start Here.

Industry 4.0 Devices Eliminate the Biggest Manufacturing Challenges

Manufacturing is tough: highly competitive and cost intensive. In addition to product innovation, to remain competitive the entire business must focus on efficiency and effectiveness to eliminate key operational challenges:

1. Downtime

Due to: equipment break-down, power failure, operator unavailability, and materials unavailability

2. Waste

Due to inefficiencies in process design (labour and equipment planning) and product design.

3. Workforce Productivity

Related to biological and behavioural patterns.

Industry 4.0 Devices Drive Smart Warehousing

Installing smart sensor environment enables stronger connection with your value chain, delivering a host of benefits in monitoring, automation and predictive analytics at each point of warehousing operation.

- Receiving Orders – Paperless processing and tracking

- Barcode Tracking – Reading and recording barcode data

- Product Locations – Eliminate waste by monitoring stock

- Tracking Inventory Levels – Eliminate costly downtime

- Picking and Packing – Smart data storage and monitoring ensures process precision

- Shipping – Automated data collection ensures data reliability

- Real-time Quantity Updates – Just hit “Refresh” button and get correct current status

FactoryWorxTM Industry 4.0 transforms Manufacturing One Sensor at a Time

With FactoryWorxTM MES software solutions the digital transformation is easy and cost effective through its inherent scalability and transparency.

Even in the most basic FactoryWorxTM configuration we include essential devices to connect your production to the business system (ERP) and to people, from operational teams to C-suite, to people and machines along the supply chain to enable you:

- Real time production visibility

- Real time reporting on critical production issues

- Better business decisions through instant data access and Predictive Analytics

- Optimised asset utilisation through Predictive Maintenance

- Increased ROI through better insights into labour, materials and energy costs.

FactoryWorx partners with leading providers of high quality Industry 4.0 devices to deliver efficient, scalable and relevant FactoryWorxTM Industry 4.0 Solutions. This provides our clients with best hardware to suit their current systems and budget. Our MES solutions are hardware agnostic and customer centric.

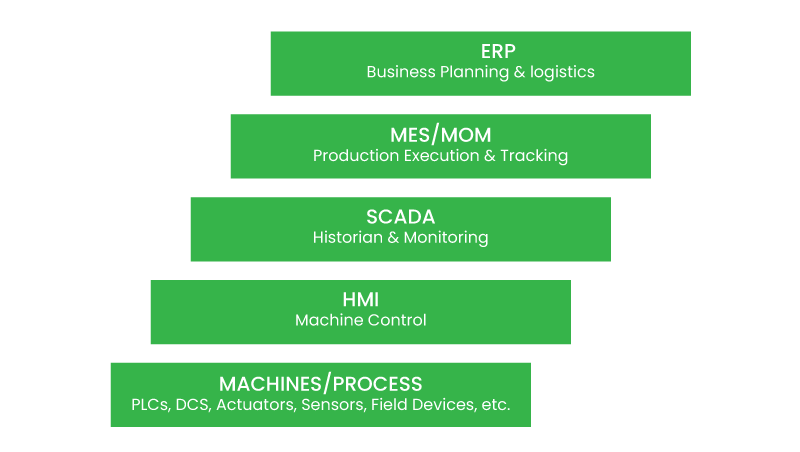

The exact architecture for your manufacturing operation will depend on your production set up, size and required capacity. However, there is the essential stack common for all IIoT enabled operations that are powered by advanced, future ready MES solutions.

Ease of Deployment – Breaking the Key Barrier to Business Transformation

Plug and play design and wireless data collection capability of smart sensor architecture ensure fast commissioning and easy device replacement with automated setting of sensor parameters. This results in a range of savings and improvements:

- Faster – instant deployment of Industry 4.0 capability

- No need for trained technical support to replace sensors

- Cheaper – no cabling or installation cost

- More efficient – Increased machine

- No downtime – increased production availability

- Remote sensor equipment configuration for standardized and reliable performance

FactoryWorx is very conscious of compliance Since there is a need for replacing batteries, it is important to include this activity in your Corporate Social Responsibility (CSR) program to ensure the brand integrity.

Key devices and elements driving Industry 4.0

The Industry 4.0 architecture requires these four groups of components:

- IO-Link Devices: master, sensors and actuators.

- Visualisation Devices: PCs, Tablets, large TV screens, etc.

- Cloud | Local Server - with wireless or cabled network.

- Endon Lights – Production line warning lights.

Opening New Horizons with Industry 4.0 Sensors

Smart sensors provide valuable insights into understanding of the equipment and environmental conditions by measuring machine input such as temperature, humidity, speed, weight, operational failures, changes in operations, object movement (target too close/too far), or valve status (open/closed). A smart sensor can also be used to improve workplace safety and productivity by reporting oxygen levels and the heart rate of employees.

FactoryWorxTM IIoT enabled solutions create a unified communications environment that provides real-time visibility and reporting at all levels of operations, to enable timely response to problems. And, importantly, it provides critical Business Intelligence inputs through predictive analytics to enable better future decisions.

Predictive analytics, collected by sensors and analysed by FactoryWorxTM MES and FactoryWorxTM AI capability, prompt informed, future oriented business decisions which lead to eliminating costly downtime and other forms of waste. And, with features like FactoryWorxTM Transportation Management and Load Builder, efficiencies flow all the way along the value chain.

Welcome to your Manufacturing future!

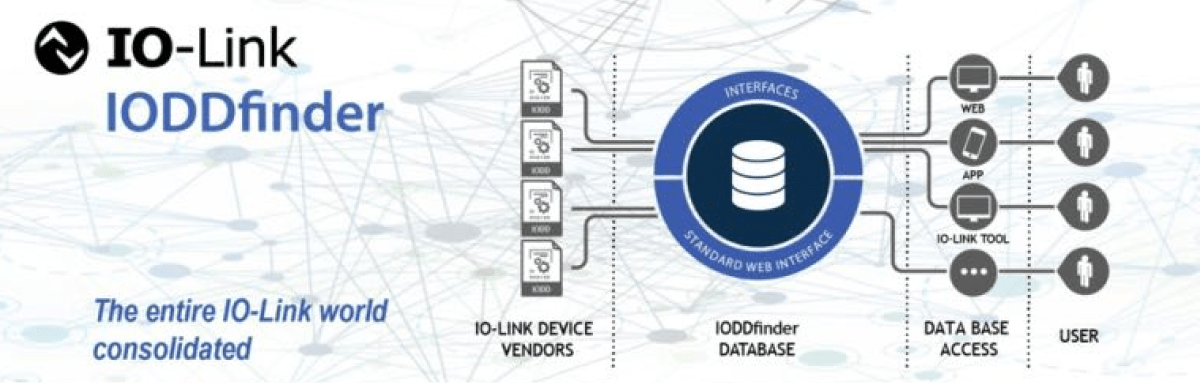

About IO Link Data Collection Protocol

With the IO-Link as a standardised gateway to unified IIoT communication Industry 4.0 is device agnostic, thus providing companies with wide choice of smart devices. What is important is the MES software that monitors and provides reporting and visibility to users. A critical element of industry 4.0, IO-Link master is a networking standard of digital industrial communications. Using digital, point-to-point, wireless (or cabled) architecture, IO-Link master and IO-Link devices, sensors and actuators, provide seamless digital communication and data transfer for highly optimized, automated and adaptable production processes and operations.

Ready to Automate Your Critical Operations?

We have a Solution just for that.

Measure and gain instant real-time insight into important data

Automated, instantly measurable quality across a matrix of factors.

Instant visibility of component and product status, quality and location.

Lean starts with no downtime preventative maintenance.

Just plug in and action insights to reduce cost and your footprint.

Optimise yield on equipment and stock for maximum