Inventory Management?

cost.

production

satsifaction.

Powerful Inventory Management with Instant Visibility & Control.

When poor inventory management systems result in extra costs or production downtime due to out-of-stock and pose a major competitive threat to business, the FactoryWorxTM Inventory Management offers a powerful and easy solution to improving the bottom line and customer satisfaction.

FactoryWorxTM Inventory Management

Inventory management is one of the core functions in manufacturing and its supply chain and therefore a key functionality of any advanced MES solution, such as FactoryWorxTM MES. It is responsible for tracing and managing inventory and stock quantities in and out of your warehouse. The key focus of inventory management systems is accuracy and control of the inventory stock, location at any given time and cost optimisation.

FactoryWorxTM Inventory Management automation and real-time inventory visibility provides superior efficiency and accountability of inventory management in the manufacturing process, from components arriving at the loading dock, to product traceability through the entire Supply Chain to the Customer.

FactoryWorxTM Inventory Management differentiates between Inventory Management and Stock Management. As these two terms sometimes cause confusion, let’s define them now. Stock Management is a subset of the overall inventory. Traditionally, stock items are considered to be the goods you sell to customers. Inventory, on the other hand, includes the products you sell, as well as the materials and equipment needed to make and deliver them to customers. While both terms are used interchangeably, inventory is a broader term.

FactoryWorxTM

MES ENQUIRY

Starting with automation or looking for a holistic MES Solution? Start Here.

FactoryWorxTM Inventory Management Supports Manufacturing and Supply Chain

The comprehensive FactoryWorxTM solution incorporates two essential facets of inventory management: FactoryWorxTM Inventory Management and FactoryWorxTM Warehouse Management System (WMS). With automation there is total visibility of everything in the factory: stock and products. SAP is not interested in where product is located.

FactoryWorxTM Inventory Management provides a complete visibility and optimisation of all stock and inventory movement associated with production and logistics.

Four Types of Inventory

While the main purpose of production and warehousing inventory management is the movement of products through production process to customer, it is more complex than that. FactoryWorxTM Inventory Management system monitors and manages four main types of inventory:

1. Raw Materials/Components– the primary type of inventory which goes into finished products and has a direct impact on cost of goods.

2. MRO supplies – inventory that enables engineering and maintenance to efficiently perform their tasks to keep production running

3. Work-In-Progress (WIP)– raw materials’ inventory that goes to finished goods, ensuring that inventory on the BOM is always available on schedule.

4. Finished Goods – refers to stock of products manufactured to customer requirements that are ready for delivery or distribution.

FactoryWorxTM Inventory Management and MRO

MRO stands for maintenance, repair and operations. In inventory management it refers to the products and tools purchased that keep an organisation running. In other words, these supplies do not become part of the end product but are used in the production process at a manufacturing plant and have a direct impact on cost of production.

Digital ability to monitor costly engineering inventory ensures ready availability of parts and can translate into massive savings and efficiencies in production. However, there is a trade-off to be calculated between availability vs cost of stock. Lean Inventory management techniques, also included in FactoryWorxTM Inventory Management, minimise stock vs availability (lead times) and cost of downtime of equipment. Effective MRO management supports core manufacturing activity.

Get Real Business Benefits with FactoryWorxTM Inventory Management

Today, transportation and logistics are not just the major cost drivers in product manufacturing but also the major risk to potential brand reputation. Investing in the advanced FactoryWorxTM Inventory Management system with a proven, built-in capability to significantly reduce these two factors is a smart and easy choice.

Increase production efficiency with timely stock availability.

Easily track inventory from loading dock to assembly lines to customer delivery.

Meet legal compliance of product traceability through automation.

Ensure ongoing customer satisfaction with always in stock.

Lower transportation cost with efficient purchases.

Reduced downtime due to out-of-stock of inventory or parts.

ERP integration for enterprise-wide analysis and planning.

Improve Supply Chain collaboration and opportunities.

Real-time inventory visibility.

Flexible Product Line Management

Track and trace products with confidence

Traceability for food manufacturing

Multi Warehouse Management

Capture all production costs

Set stock levels

Maintain Stock Visibility

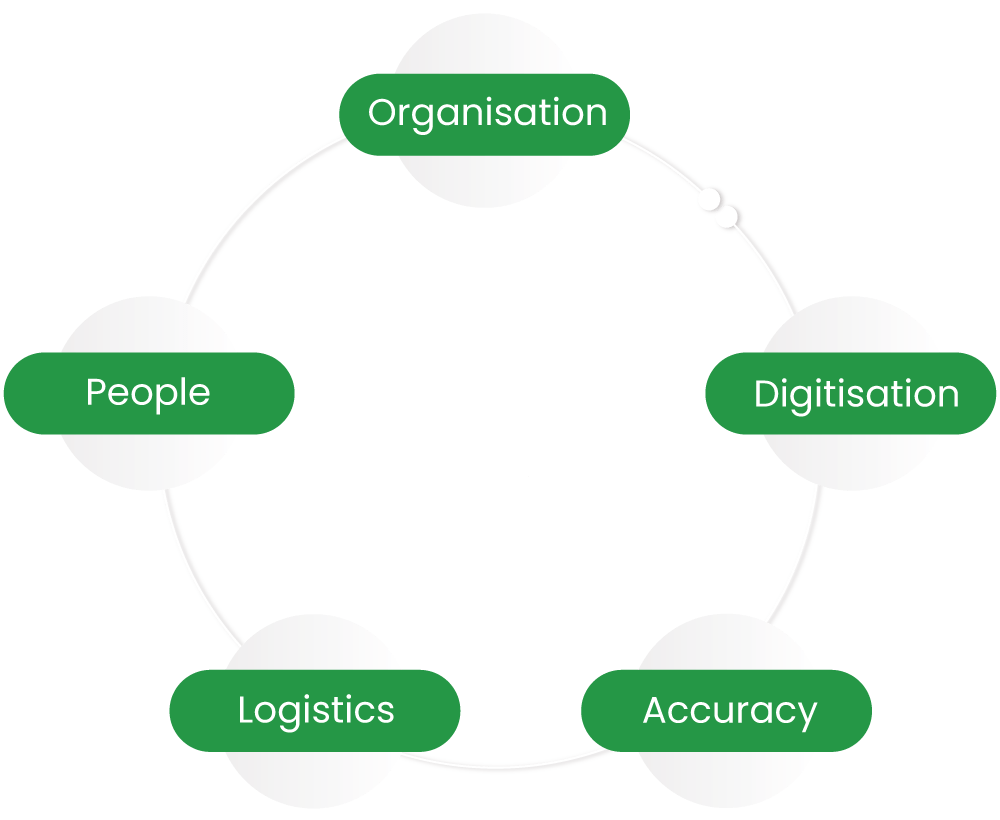

FactoryWorxTM Inventory Management – Functionality Overview

The FactoryWorxTM Inventory Management System supports manufacturing and warehousing operations beyond just handing you a great, intuitive software.

In order to leverage this powerful tool, FactoryWorx has structured software functionality around the key functions that bring the physical and digital environments together.

Organisation

Organising Inventory enables your company to build an optimized structure in which inventory is organised and Executed for Efficiency and KPIs. FactoryWorx software enables best practice configurations for most efficient storage layout aligning digital with physical functionality, with consideration of actual warehouse capacity, volume of goods (including and hazardous goods) that can be stored, Barcoding locations – printing and coding, distances in the warehouse. It also takes into account multiple warehouses in the operations.

Organisation of inventory comprises several areas:

1. Layout

2. Location control and management

3. Visibility of product movements through production

4. Managing life of inventory

5. Batch picking – to optimise activity and improve efficiency

6. Warehouse layout – to improve efficiency

Digitisation

FactoryWorxTM Inventory Management software transforms paper-based systems into digital environment, with barcode scanning to quickly acquire and process information. It fully aligns digital and physical of inventory and products, providing enhanced:

1. Product control – using the current version of Bill of Materials (BOM)

2. Inventory control

3. Visibility and Reporting

4. Timeliness of information - with real-time, digital tracing that reduces the risks of human errors and enables product traceability at any time to meet legal compliance.

Accuracy

FactoryWorx system enable accurate inventory and stock accountability and visibility, based on several criteria, which while critical in some industries (e.g. food manufacturing and pharmaceuticals manufacturing), have financial importance in every industry.

FactoryWorxTM Inventory Management measures and provides insight to eliminate discrepancies in the Accuracy of inventory management. These Stock Variances have a direct impact on production efficiency, cost of maintenance, cost of stock and affects cash flow, product quality and deliverability and, ultimately, customer satisfaction.

See instant improvements in all areas of Inventory management:

1. Stock level – the emphasis here in on accuracy of stock level. An efficient system should report in real-time on actual stock levels without missing an item that has been misplaced.

2. Location - The system is able to trace an item to its actual physical or digital location using barcode scanning and other technologies.

3. Correct product – our intelligent inventory management ensures that correct product is delivered, scheduled into production and despatched to the customer.

4. Shelf life – using appropriate inventory management techniques, such as FIFO, reduces waste and extends the life of product.

5. Stocktake – as a periodic activity that traditionally supported financial requirements it has always been labour intensive and had little impact on usability of stock uncovered in the process. Digitised stock take can reduce the cost and be performed any time to bring any variances in line with physical status.

6. Cycle count – Cycle count is like constant ‘mini stocktake’. Performing incremental checks on inventory increases efficiency and accuracy of stocktake. Reduces the need for stocktake frequency. See below for more details on Cycle Counts and Reporting. Cycle count can be automated whereby the system will instruct operator to count, or manual, where the supervisor instructs an operator.

7. Small items vs bulky items – inventory management systems can automatically differentiate between these types of goods and can schedule more efficient picking, analyse and improve on this time-saving activity via reports.

Logistics

While Logistics Management is a separate FactoryWorxTM MES Module such, provides extra functionality, it is also an integral part of FactoryWorxTM Inventory Management. It provides three critical features. FactoryWorx system builds digital memory or product/stock location and movement (traceability), providing enterprise-wide visibility and insights for optimised tactical and strategic decision making.

1. Delivery – providing insights and management of traceability and compliance requirements associated with Chain of Responsibility, COR.

2.Product scanning – providing digital location data for picking, packing and distribution.

3. Delivery to location – digital, automated confirmation

People

An inventory management system is directly connected to only as good as the effectiveness of people handling the tasks.

FactoryWorxTM Inventory Management software helps you organise and manage the execution of people-related activities. Embedding this element of digital inventory management leads to improvement in labour planning and utilisation as well as improving their skills.

Upskilling the workforce, leads to drastically reduced cost of labour when using FactoryWorxTM AI to run ‘dark factories” and “dark warehouses”.

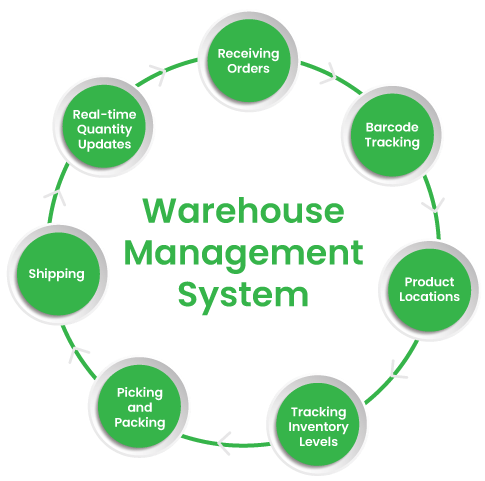

FactoryWorxTM Warehouse Management System - Process Features

- Receiving Orders

- Barcode Tracking

- Product Locations

- Tracking Inventory Levels

- Picking and Packing

- Shipping

- Real-time Quantity Updates

FactoryWorxTM Inventory Tracking System

FactoryWorxTM Inventory Tracking System is one of the key feature of FactoryWorxTM an automatic inventory controller, consisting of digital processes and policies designed to monitor the movement of inventory. So, whenever an inventory transaction occurs, the inventory system gets an automatic notification of the transaction. This eliminates the risks of the human error and effectively replaces the old manual card system.

LEVERAGE THE POWER OF TIMELY INSIGHTS

Reporting with FactoryWorxTM Inventory Management

The powerful reporting features of FactoryWorxTM Inventory Management System provide operators and management with instant, and easily accessible range of reports to enable rapid response to operational requirements and to make accurate decisions regarding inventory purchasing.

Bulk Picking Report

This report groups together items that frequently ship so that shipping costs and lead times are reduced. It also reduces the time employees spend in picking product for shipping by locating fast moving products in the most time efficient ways so that employees don’t pick the same product over and over, eliminating wasted steps.

Labour Report

This report is used for planning your labour force efficiently. You can use it for making hourly, weekly, monthly, and seasonal adjustments to your labour force. Use this report to predict how many employees you need at a given point and only use the workforce you need.

Inventory on Hand Report

This reports on the amount of inventory available for shipment at any given time. This report can be used to adjust your inventory due to miscounts, theft, or other mishaps. Setting inventory maximums and minimums reduces slow moving inventory that sits too long, while also reducing instances where items are on backorder.

This report shows those counts that were entered and ACCURACY – INVENTORY MANAGEMENT

Cycle Count Reports

FactoryWorxTM Inventory Management reporting functionality you can use various reports to optimise the process of cycle counting and to analyse and report the results of cycle count transactions.

Cycle Count Schedule Requests Report

This report shows all schedule requests for a specified time. It includes both manually and automatically scheduled items.

Cycle Counts Pending Approval Report

are currently pending approval. The supervisor with the authority to approve cycle count adjustments would typically run this report regularly to monitor the approval queue.

Cycle Count Open Requests Listing

This report shows count requests where no counts have been entered, or count entries where you have requested a recount. You can optionally report on late counts, where no counts have been entered and the due date for the count entry is before the date of the report.

Cycle Count Hit/Miss Analysis

his report shows, for each cycle count class, the total number of count entries and the number of counts outside the limits of the user-specified hit/miss tolerances.

Empty Bin Report

This report allows warehouse operators to see what space is available for incoming shipments, assisting in decreasing put-away time by eliminating the need to drive around the warehouse looking for an empty bin. This report is very beneficial, especially to 3PLs. It allows warehouse operators with multiple tenants to identify and utilize the space available in the most efficient way possible to increase profits.

Why Inventory Management is critical in Manufacturing

Few people in manufacturing would need to ask why Inventory management is important in their operation and the Supply Chain. Yet, a surprising number of manufacturers and warehouses are not leveraging the fantastic potential of an automated, digitised Inventory Management system to save cost, time, stress and, ultimately to secure customer satisfaction.

If your operations even occasionally experience production downtime due to shortage of stock or machine spare parts, getting wrong parts, incorrect stock counts, mis-shipments, out of stocks, overstocks, mis-picks, and so on, clearly you need a solution. A good warehouse management is key, one that easily integrates with other systems and will take you well into the future.

Discover what FactoryWorxTM Inventory Management can do for your operations!

Schedule a tailored DEMO with our Expert.

Which Inventory Management Techniques Do You Need to Use?

Just how critical is accuracy, relevance and correct insights into Inventory Management is reflected in the large number of techniques companies try to apply to get the right answers. Unlike many Inventory Management systems focus on one or a few of these techniques, FactoryWorxTM Inventory Management can accommodate any of your requirements.

- Economic Order Quantity

- Minimum Order Quantity

- ABC Analysis

- Just-In-Time Inventory Management

- Safety Stock Inventory

- FIFO And LIFO

- Reorder Point Formula

- Batch Tracking

- Consignment Inventory

- Perpetual Inventory Management

- Dropshipping

- Lean Manufacturing

- Demand Forecasting

- Cross-Docking

- Bulk Shipments

- Lean Six Sigma

What You Need To Know About Inventory Management Techniques

You are no doubt using one or more of these techniques, but potentially as a manual or inadequate computerised system. While FactoryWorx can support you in whatever your best practice requirements are, there are just a few facts you may find useful.

1. Average Quantity System (AQS) – Compliance Benchmark For Food Manufacturing

The Average Quantity System (AQS) confirms the measurement or quantity of packaged goods being sold by measure (weight, volume, length, area, or number). It is an internationally agreed method of determining the size or quantity of pre-packed articles with a ‘constant nominal content’. The Average Quantity System (AQS) provides confirmation of the measurement or quantity of goods in the package, being sold by measure (weight, volume, length, area, or number).

Under Australia’s trade measurement legislation, manufacturers, packers, and importers must use either: the Average System or AQS (The average net content).

2. What Is Economic Order Quantity (EOQ)

Economic order quantity (EOQ) is the ideal order quantity a company should purchase to minimize inventory the cost of carrying inventory and the processing of purchase orders or production set-ups. The formula also takes the number of units in the delivery of and storing of inventory unit costs. This helps free up tied cash in inventory for most companies.

3. FIFO and LIFO

The LIFO and FIFO methods not only help determine the cost of inventory. FIFO, or First in, First out, also helps control and ensure the older inventory is used and sold first. FIFO is a great way to keep inventory fresh.

The FIFO method is the most popular inventory method because it reflects the actual movement of inventory for most businesses. It is one of the most common methods of inventory valuation used by businesses.

If you (or your Predictive Analytics) expect inflation, the FIFO method yields a higher value of the ending inventory, lower cost of goods sold, and a higher gross profit.

4. Just-in-time inventory management (JIT)

Just-in-time (JIT) inventory management technique that coordinates raw material orders from suppliers with production schedules is increasingly connected to Lean Manufacturing. While it is a great way to reduce inventory costs, it also exposes manufacturers to risks of unexpected costs of failures in the supply chain. Predictive Analytics, which leverage IoT integrations and big data that provides insights which are outside your own operation, is a viable solution to avoid these risks.

5. Batch tracking

This is an incredibly valuable technique that enables product traceability. As a quality control technique it enables companies to group and monitor stock with similar traits. You can track the expiration of inventory or trace defective items back to their original batch through the Supply Chain. Obviously, your Inventory Management needs to be able to integrate with IoT technologies and diverse systems within your Value Chain. We can help.

6. Lean Manufacturing

This technique, in line with principles of Lean Manufacturing, aims to improve efficiency by eliminating waste and any non-value-adding activities from daily business. FactoryWorxTM Inventory Management system, through its Organisation functionality, enables to design inventory physically and digitally to achieve Lean KPIs.

7. Lean Six Sigma

It is important to keep in mind that while Lean Six Sigma uses and enhances the tools of Six Sigma, it has a strong focus on instead embedding standardization in the flow of business. This is significant as it underpins the future of Manufacturing, i.e. Industry 4.0.

PEOPLE ALSO ASK

Questions about FactoryWorxTM Inventory Management

FactoryWorxTM software integrates with any system and information that is appropriate for you and your industry.

We also use the average landed costs methodology.

Yes. FactoryWorxTM software leverages IIoT devices and scanning technologies, such as barcoading, that enable you full visibility of your stock and inventory anywhere on the production or warehouse floor.

Easy. FactoryWorxTM reporting will enable you to use Stock-on-Hand enquiry report. Or you can use an Item enquiry report to gain instant visibility of available stock.

Yes. FactoryWorxTM reporting feature lets you see the full transaction history of serial and batch number, when they were created, when were the products sold/dispatched to customers, or deleted.

Deploy FactoryWorxTM Inventory Management at Your Pace

The best aspect of this exceptional manufacturing solution is its flexibility. While some companies are ready to go full throttle into full Industry 4.0 transformation, and beyond; adopting FactoryWorxTM Inventory Management one functionality at a time, is a very viable option. Each of these functionalities is an independent mini-MES Module that enables implementing automation and new efficiencies where they are most needed.

If you choose to get a DEMO to see FactoryWorxTM Inventory Management in action, our expert will show you the best way to address your most challenging or annoying manufacturing issues.

SEE THIS SOLUTION IN ACTION!

Want to see how it all works and what it can do for your company?

Schedule a tailored DEMO with our Expert.

WHAT IS YOUR KEY MANUFACTURING CHALLENGE?

We Have the Solution

Fully optimised production planning, visibility, control.

Measure and gain instant real-time insight into important data.

Automated, instantly measurable quality across a matrix of factors.

Instant visibility of component and product status, quantity and location.

Seamlessly integrates with major ERP and known business systems.

Industry 4.0 enabled, real time production environment visibility.

Control product progress/cost from components to despatch.

Faster, always accurate and reliable digital factory operations.

Lean starts with no down-time preventative maintenance.

Just plug in and action insights to reduce cost and your footprint.

Optimise yield on equipment and stock for maximum

Empower people to see the bigger picture, their progress and support.

FREE TRIAL

Test FactoryWorx Core Modules inn Your Operations

Try Before You Buy. Adopting new, advanced MES, Manufacturing Execution System, whether as a single function or entire Industry 4.0 transformation, is a major business commitment. It’s not just cost, but also potential disruptions, increased workloads and a steep learning curve. Not with FactoryWorx!

Energy Management

production Planning

OEE Reporting

Manufacturing Dashboard

See the Simulation first in a Personalised DEMO.

Take the Next Step Towards Manufacturing Excellence

Well, what now? Sitting on the fence is not going to solve any problems. They are just going to get bigger.

The fact is that the choice of the best MES solution for your manufacturing operation is easier than you think. FactoryWorx modular, scalable MES platform can rapidly transform manufacturing companies into Industry 4.0 leaders. It is recognised for its comprehensiveness and exceptional value by some of the leading brands as well as small manufacturing operations.