- November 15, 2021

- admin

- 0

Read FactoryWorx Blog

How Production Dashboard Helps a Manufacturing Industry?

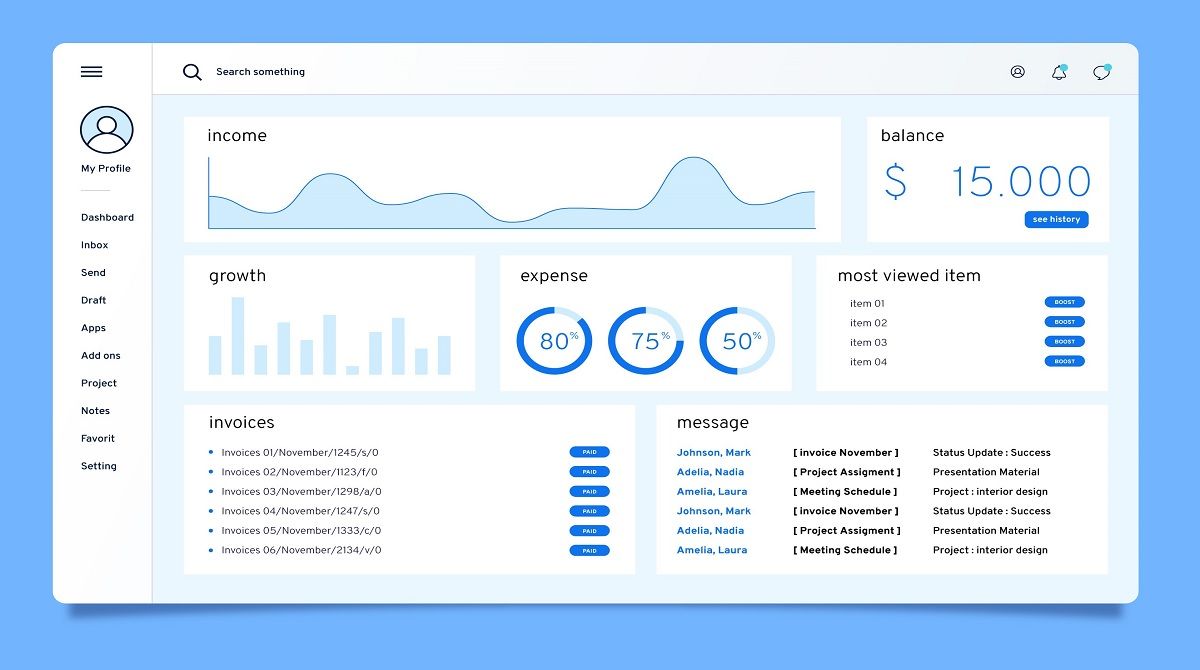

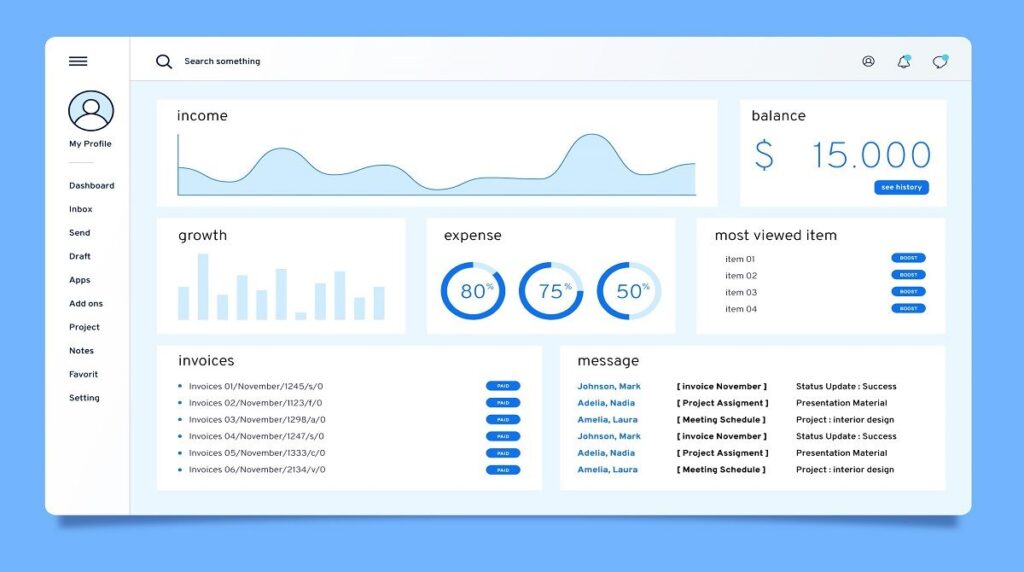

Experts define a digital production dashboard as an intelligence tool that allows business leaders to track, analyze and report on key performance indicators (KPI) and other key metrics. The latest versions combine data from multiple sources and analyzing of data within the dashboard. Data from machines, sensors, devices and workers are organized and converted into easy-to-read data.

Experts suggest the use of manufacturing dashboards, as it helps the management in more than one manner. They need not spend hours gathering and analyzing manufacturing data. The specially designed dashboard provides all the data.

This blog helps you understand why digital dashboards matter and how they help the manufacturer and the management.

Why do digital dashboards matter?

Experts in the field believe that digital manufacturing dashboards are effective tools that optimize the manufacturing process. With better availability of required information, the management or the staff can make better decisions. In most cases, they give the highest priority information, which is available quickly, allowing timely actions.

An ideal dashboard provides a wide range of data, from simple to complex. This dynamic visual is easy to understand. It helps improve the manufacturing process's efficiency and aid supervisors in spotting troublesome areas. They can also offer feedback to adjust strategies and encourage a dialogue between floor workers and management for setting realistic expectations. They further help make the best use of the plant and aid in detecting the causes behind the bottlenecks and defective products. In short, they prove to be an ideal manufacturing reporting system.

The dashboards put forward the most valuable information to the forefront, allowing the manufacturers to concentrate on KPIs, which is critical to surviving in this competitive market. It proves to be worth every rupee spent for owning such production monitoring software.

Why does digital dish board provide a win-win situation always?

The age-old technique includes a whiteboard, a staple of the factory floor, mounted on a wall at a central location. The information on the whiteboard is updated many times a week or a few times a day, which includes planned and actual production numbers and important floor information. Frequent updating of information is critical on the floor. If an individual forgets to update the information, critical numbers will not match and require hours of cross-checking to get it right. All the actions are done manually, which can lead to errors or sensitive data being lost.

The modern manufacturing dashboard provides all the necessary information that a whiteboard gives but eliminates all the drawbacks of the traditional technique. The different ways in which digital dashboards are better than whiteboards are:

- Real-time updates.

- Automatic calculations, such as time required for completing a production cycle, number of employees and production-hours to meet the target, scheduling the deadline, number of defective products and spotting of bottlenecks and many more.

- Accurate and readable data.

- Long-term trends can be seen using data.

- Provide insight or prediction with the available data.

- High-resolution screens to enhance visibility.

- Remote viewing capability allows the management to keep themselves updated with the latest data.

Production dashboards have proved to be a valuable analytics tool for most manufacturing unit owners if they use them wisely. In simple words, if the manufacturer uses the dashboard to display easy-to-understand, relevant, and high priority information, which can be helpful to the on-floor staff members.

The software developers provide clients with a customized manufacturing dashboard. It can provide information related to production and stack availability, visible to the shop floor. It further can give long-term details, which gathers the interest of the investors and stakeholders. The dashboards can be configured with the necessary information, depending on the audience. The use of different colours helps in the easy understanding of data.

If you are thinking of installing this type of manufacturing reporting system, it would need data from the shop floor (utilization trends, possible machinery complications, production capacity etc.), machine data, and market target. Hiring a professional aid in making the best use of the equipment and plan to meet the targets!