Team Collaboration?

effective Meetings.

Project Automation.

Strategic level.

Empower people to nail their goals and see the bigger picture.

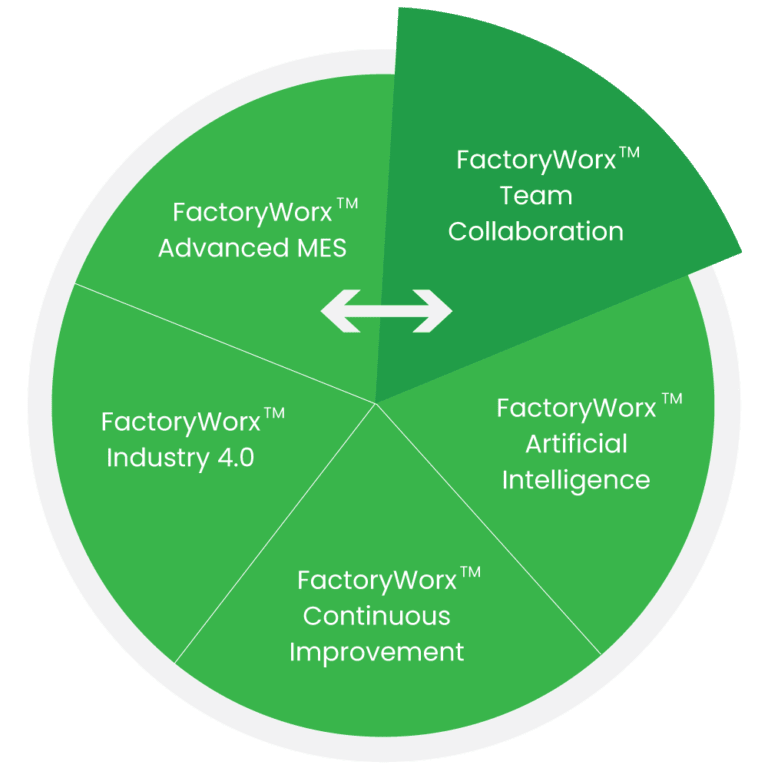

As the pace of business quickens with automation, improving people and team collaboration remains the holy grail for management. In the win-or-perish race to the next level of efficiency and innovation advanced Team Collaboration tools such as FactoryWorxTM Team Collaboration are seen as a must-have answer.

What are Team Collaboration Tools?

The term Team Collaboration Tools covers a range of software designed to enable groups of any size to work together toward a shared goal in focused environment. Team Collaboration software is usually cloud-based and allows users to access the platform, contribute and share relevant information anytime, from any internet-enabled location.

Most Team Collaboration solutions specialise in one of three functionalities: Communication, Document Sharing, or Project and Task Management.

Why Team Collaboration Tools Are a Big Focus for Business Today?

While companies of all sizes increasingly transform their operations to Industry 4.0 automation, one critical element still eludes them: the human factor. As people remain the most valuable game piece in business creativity and innovation, focusing and tracking their performance for improvement where it adds most value, is the biggest challenge across all companies. The ability to bring a significant element of automation to human interaction is one of the key advantages of FactoryWorxTM Team Collaboration software.

FactoryWorxTM

MES ENQUIRY

Starting with automation or looking for a holistic MES Solution? Start Here.

Introduction to FactoryWorxTM Team Collaboration Platform

FactoryWorxTM Team Collaboration is a paperless work management solution that helps teams stay focused on important goals, projects, and daily tasks that grow business and provide individuals with measurable sense of achievement.

FactoryWorxTM Team Collaboration is recognised as a specialist solution for manufacturing. As part of FactoryWorxTM Advanced MES platform, our Team Collaboration software leverages the powerful integrations capability of MES to help people across the organisation Get Organised, Stay on Track and Meet Deadlines.

FactoryWorxTM Team Collaboration is often implemented alongside FactoryWorxTM Continuous Improvement module with which it shares lean and agile tools.

FactoryWorxTMIntegrations provide a seamless pipeline for translating results of collaboration into manufacturing excellence and success.

HELPING PEOPLE SUCCEED AT WORK

Benefits of FactoryWorxTM Team Collaboration Platform

- Effective because they connect people in purposeful, focused collaboration

- Connect the entire team from top to bottom

- Provide a channel for communication at both the individual and team levels

- Enable remote employees as well channel partners to participate

AUTOMATION FOR THE HUMAN FACTOR OF THE BUSINESS

How FactoryWorxTM Team Collaboration Helps You Increase Productivity

FactoryWorxTM Team Collaboration shines at facilitating effective and efficient communication through simplicity of process, automation and the all-important integrations that connect Teams directly to information and physical operations.

Integrations

Connecting People with Data & Business Systems.

Business Systems:

ERP, BI Systems, Master Data, Product and Process Information

Production Systems:

FactoryWorxTM MES, Production Reporting, Dashboards, Quality Management

Strategy & Innovation:

FactoryWorxTM Continuous Improvement, Invite Clients, Suppliers, Customers

OUTCOMES-DRIVEN COLLABORATION

FactoryWorxTM Team Collaboration – Freedom to Succeed

FactoryWorxTM Team Collaboration support teams, individuals and the entire organisation in the quest to succeed and get things done easier, faster, and ultimately enjoy work more. We make it simple with a fully digitized three-steps approach.

Get Organized:

Plan and structure work in a way that’s best for your team to achieve the shared goal. Automatically set meetings, projects and tasks with pre-built templates. Assign tasks and deadlines. All in one place. Execute projects with Lean Six Sigma ‘DMAIC’ model. Get Organised comprises four elements.

- Meetings (SMART)

- Tasks

- Project Management

- PerformanceManagement – strategic level only using Balanced Score Card

Stay On Track:

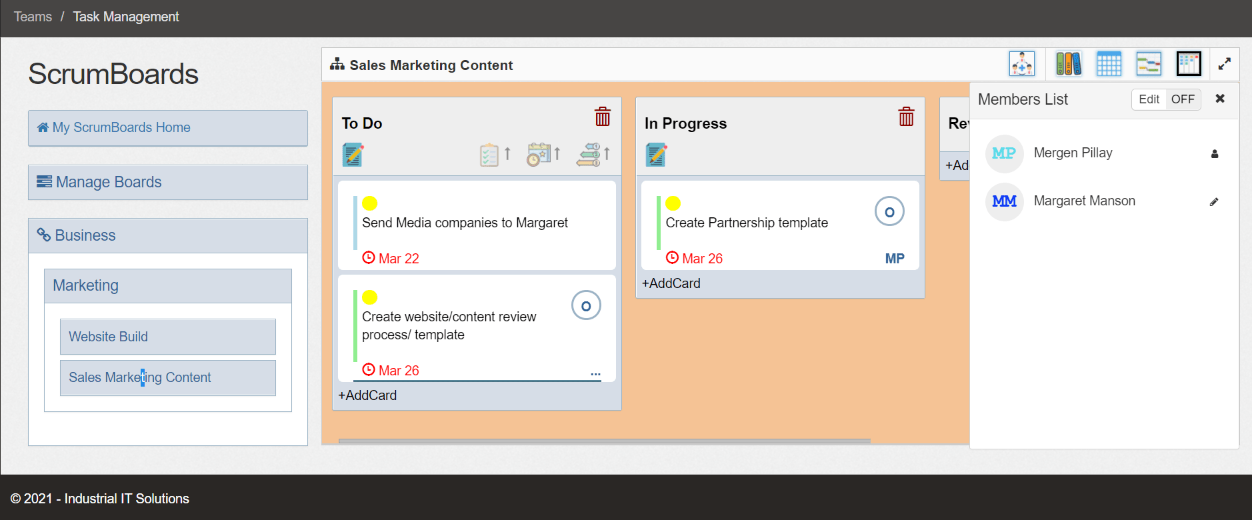

FactoryWorxTM Team Collaboration enables contributors to follow their projects and tasks through every stage using native Scrum Boards or Kanban Boards for agile task management. People can see their tasks live on real-time project boards and Project Managers can easily see the overall projects and can keep everyone aligned on goals. The software itself manages this process with automated notifications.

Meet Deadlines:

Every step in this process, facilitates meeting deadlines for project and for individuals. It is achieved through visual project plans, using Scrum Boards. They enable everyone involved in a project to see how every step maps out over time. FactoryWorxTM Team Collaboration software shows backlogs, pinpoint risks, shows path to eliminating roadblocks. It is always up to date and automatically notifies all contributors when plans change.

MEETINGS DIGITISED

FactoryWorxTM Team Collaboration – Meetings

FactoryWorxTM Meetings help organisations optimise this function with clear process and automation. The process follows the best practice process for effective meetings using intuitive digital approach.

The Digitised Process:

- Objective Management – follow a pre-built template to set up the objective for effective meetings.

- Agenda Setting – use pre-fill content in agenda templates, standardised for different types of meetings.

- Meeting Management – the system takes care of invitations and distribution of tasks and minutes after the meeting. Create Minutes in minutes using a pre-built template. Automatically allocate Tasks directly from meeting notes. Automatic notifications about tasks sent as soon as the minutes are posted.

- Reward Contributions – Star-rating feature enables rating individuals’ project contribution performance.

Benefits:

- Instead of having daily meetings – people check in online in Task Manager. Just calculate the hours saved and converted into productive activity.

- Time savings for Managers in automation of meetings coordination.

- Automatic notifications about tasks – outstanding and new, and changed – no missed emails and deadlines.

TASK MANAGEMENT DIGITISED

FactoryWorxTM Team Collaboration – Tasks

FactoryWorxTM Task function uses native Scrum Boards or Kanban Boards for agile task management. It keeps visual record of scheduled tasks, with accountabilities assigned to specific people, with due times as agreed in project meetings. And it enables limitless collaboration. Project Team can include people from outside the organisation: suppliers, consultants, experts, and even customers.

Importantly, you are already running MES software, preferably FactoryWorxTM MES , you don’t need to introduce another 3rd party Collaboration app to get your Team to work effectively. Using one FactoryWorxTM Team Collaboration platform provides people with best visibility of Production and Business, to help them achieve important goals easily.

Benefits:

- No extra subscriptions

- No extra integrations or need to maintain another piece of software

- No more recording and fragmenting your data among separate sources and systems

- Keep your data secure and ensure you retain it when you change provider.

- No more emails cluttering inboxes.

- No more missed tasks or deadlines with automatic reminders and alerts.

- Complete focus and productivity.

PROJECT MANAGEMENT DIGITISED

FactoryWorxTM Team Collaboration – Projects

Manufacturing companies run on projects. Traditionally, meetings and communication have been the two biggest challenges for Project Management efficiency.

FactoryWorxTM Project solution puts an end to these challenges with easy, user friendly and effective automation. It automates project management by digitising Lean and Agile process and tools to deliver both agility and quality of outcomes.

FactoryWorxTM Project is designed on the principles of the DMAIC Lean Six Sigma model.

Define

Define the problem

Measure

Quantify the problem

Analyse

Identify the root cause of the problem

Improve

Implement and verify the solution

Control

Maintain the solution

Features:

FactoryWorx Project can create any digital project structure for your industry niche or project team and pre-populate it with best practice content. This includes any of the popular Lean project methodologies, e.g. A3, KT, Prince, etc. the software features most of the popular lean tools and we constantly add new ones as they become more broadly relevant.

- Digitised Lean A3 form

- Lean widgets

- Pre-built A3 ‘Buckets’. Some of the pre-built, digitised tools include:

- Root cause analysis tool: Fishbone diagram and 5 Whys

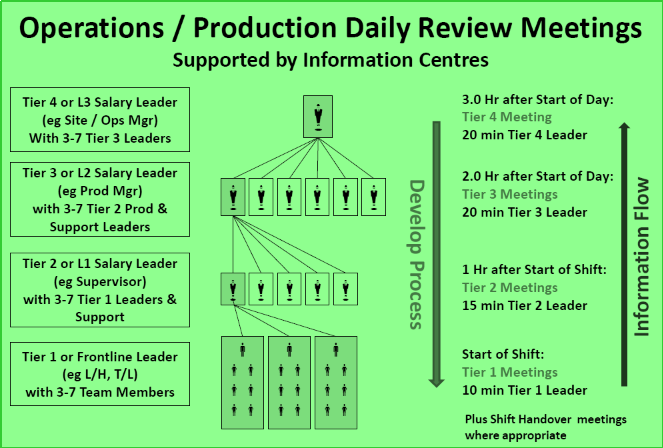

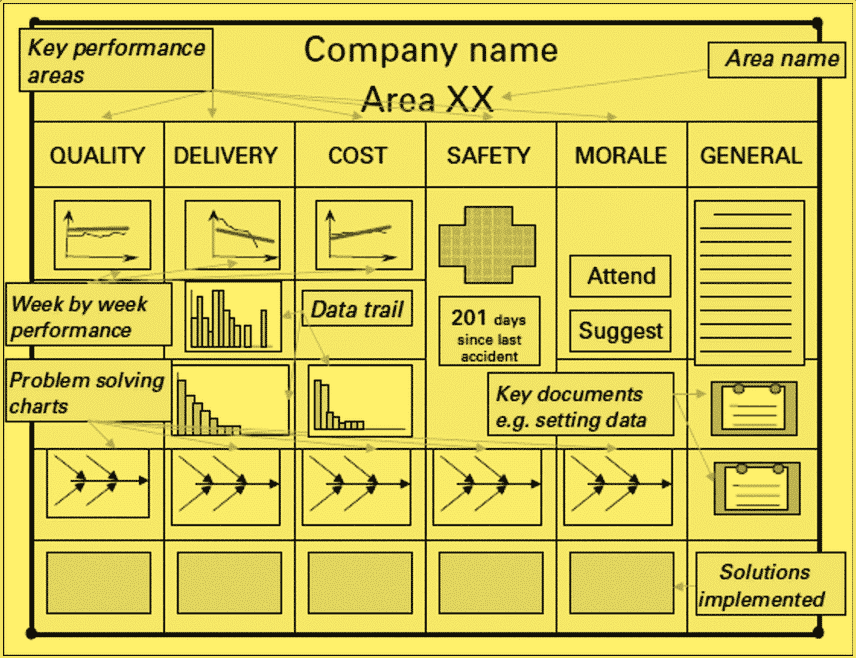

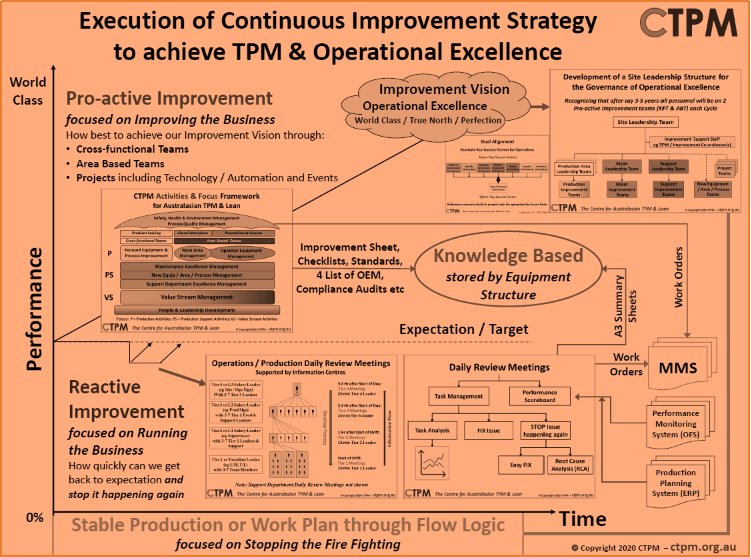

- Daily review meetings

- Production Daily Review Meetings

- The Activities and Focus Framework (the “Hamburger”)

- Strategy and Goal Alignment – Cause/Effect KSFs diagram

FactoryWorxTM Project – Process and Benefits:

- Project is created - using digitised standard Lean Tools or modified, proprietary project methodologies, all of which can be easily adapted to FactoryWorxTMProject templates.

- Managing the project– follows a best practice Step by step process, usually a digitised Lean A3 form.

- Software as a Project Manager– software takes over some of the critical yet mundane responsibilities of a Project Manager, including coordinating teams through automatic notifications and smart content management.

- Managing utilisation of people– software monitors the project based on pre-programmed best practice values. It evaluates the number and importance of tasks allocated do various people, communicating insights on whether tasks have been allocated fairly and responsibly.

PERFORMANCE & STRATEGY IN AUTOMATION AGE

FactoryWorxTM Team Collaboration – Performance Management

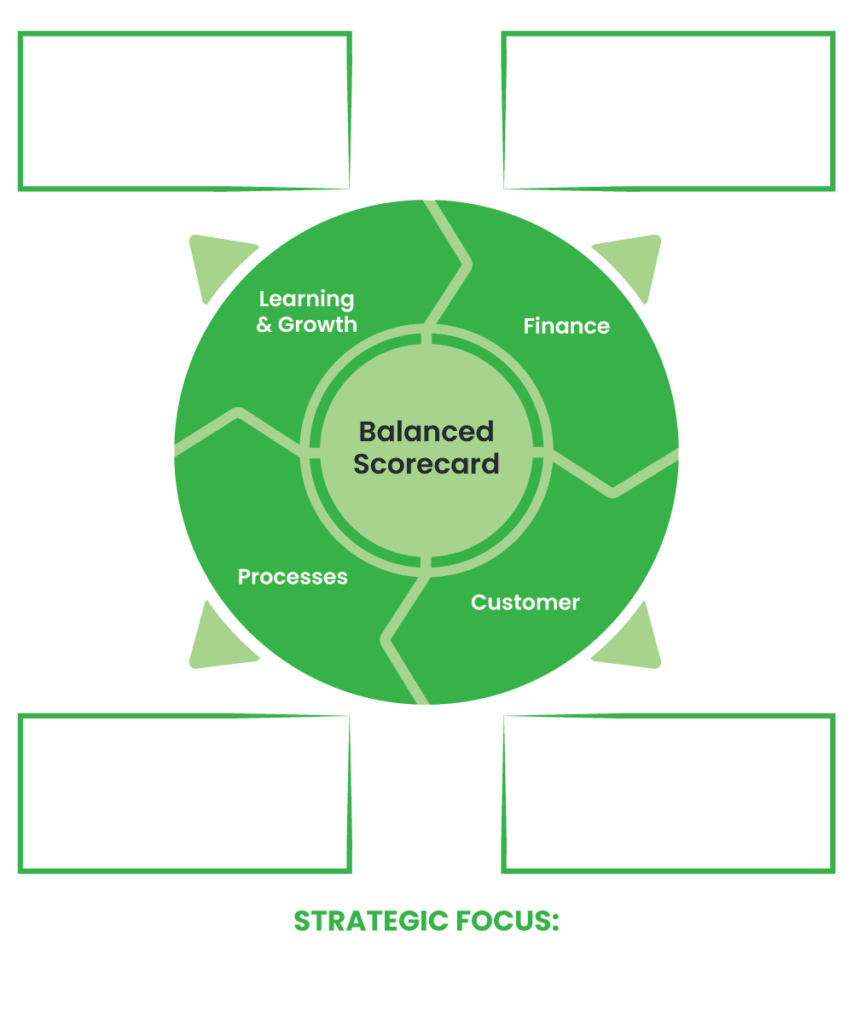

Performance Management on a strategic rather than labour cost level is a unique feature of FactoryWorxTM Team Collaboration module. It digitises the Balanced Score Card methodology that defines how you use objectives to manage performance.

What is a Balanced Scorecard?

The Balanced Scorecard (BSC) is a relatively new approach to strategy. It is a more holistic system for managing strategy. It considers soft metrics, such as Customer and Employee satisfaction, learning and culture and uses cause-and-effect logic of goals and outcomes, rather than traditional KPIs.

Balanced Scorecard is better at “connecting the dots” and showing the correlation between KPIs of projects and programs people are working on, strategic objectives the organization is trying to accomplish, and the mission, vision, and the strategy of the organization.

The three core strategies of Balanced Scorecard are the source of Business Objectives |Goals. Goals are formulated using major business challenges and trends in any of these areas:

- Product Leadership

- Customer Relationship

- Operational Excellence

The Cause-And-Effect Logic and the Four-Pillar Strategy Model of Balanced Scorecard

FactoryWorxTM Team Collaboration standardises and automates the Balanced Scorecard process with clear metrics and desired impacts inputs/outputs across the four-pillar strategy.

Financial Accountability & Stewardship

- Metric: Financial performance, ROI, cash flow

- Impact: Effective use of Resources

Customer & Stakeholders

-Metric: Customer Value

- Impact: Satisfaction / Retention

Internal Process

- Metric: Efficiency

- Impact: Quality (Consistent & Perceived)

Learning & Growth

-Metric: ROI on Human Capital, Technology, Innovation, Job Satisfaction, Employee turnover, Training & Skills

- Impact: Culture is a Source of Competitive Advantage

Understanding The Difference between Project and Performance Functionality:

| Strategic Elements | Projects Use KPIs | Strategy Benefits from using Balanced Scorecard |

|---|---|---|

| The Purpose | Measure business performance from KPIs perspectives | Goals set based on cause-and-effect between strategic problem and wanted outcomes, measuring performance based on progress towards achieving Goals. |

| Four Perspectives Structure | Yes | Yes |

| Cause-And-Effect Logic Between Perspectives | No | Yes |

| Main Focus | On KPIs | On business goals |

| Cascading | By KPIs | By business goals |

| Approach To Execution | Driven by KPIs. Managers are focused on measurement, business; context comes later | Focus on business context (goals); measurement comes later to make goals more specific and tangible |

| Visual Communication Tool | Dashboard | Strategy Map |

Harness the Strategic Value of Balanced Scorecard with FactoryWorxTM Performance

Process:

- Define Vision and Objectives

FactoryWorxTM Performance (Strategy) function enables you to easily set up your Strategic Objectives. While similar to Projects, Performance structure and process flow is based on Balanced Scorecard. There are significant differences to purpose, process and outcomes we measure.

- Select your Strategic Team

As a strategy tool, Performance allows you to selectively invite people to participate in the process. Usually, it starts with job Level T3 (Department Managers and Plant Manager or higher) and cascades to Level T2 (Supervisors and Department Managers), and rarely to T1 (Operators and Supervisors).

- Strategy Development and Execution Process

Unlike Projects that run on Scrum Boards, Strategic Project also addresses Financial, Customer and Learning aspects of business. However, Strategic Projects can use FactoryWorxTM Scrum Boards to manage the process. Scrum Boards are progressively replacing old project management tools because they are faster and not as linear.

Benefits of Using Balanced Score Care with FactoryWorxTM Performance

- Easily set up and communicate Vision and Goals

- Align the day-to-day work with strategy

- Prioritize projects, products, and services based on Goals

- Measure and monitor progress towards strategic objectives and targets

FactoryWorxTM Performance provides a digitised process to measure and drive improvement of value-adding activities of individuals and teams.

Benefits with FactoryWorxTM Team Collaboration

Implementing the FactoryWorxTM Team Collaboration system has a positive, direct impact on every aspect of an organization's performance. While the value of a documented Team Collaboration system is common knowledge, FactoryWorxTM Team Collaboration brings magnified benefits through digitisation, automation, IIoT connectivity and integrated, scalable capabilities of FactoryWorxTM MES, Continuous Improvement and Industry 4.0 platforms.

Uncluttered simplicity - easy to learn and use

Increased Team performance – focused virtual workspace to work on shared goals

Native Scrum Boards improve agility of Projects and Tasks - visibility and easy management of Backlog items

Increased project efficiency and effectiveness - software performs the many tasks of a Project Manager

Improve efficiency of Meetings - automated preparations of agenda, invitations, task management, minutes - generating and distribution

Create and manage projects automatically

Create and manage Strategy using digitised Balanced Scorecard.

Add agility to Strategy Projects with Scrum Boards

Find out what FactoryWorx can do for YOU!

Want to see how it works and what it can do for your company?

Schedule a tailored DEMO with our Expert.

Deploy FactoryWorxTM Team Collaboration on Your Terms

One of the most valued benefits of FactoryWorxTM MES Modular solutions is flexibility. You can easily deploy one functionality at a time, starting with FactoryWorxTM Team Collaboration. Each Module is independent and will enable you to deploy automation and efficiencies where they are most needed.

Request a DEMO to see FactoryWorxTM Team Collaboration in action. Our expert will show you the best way to address your most challenging or annoying manufacturing issues.

Take the Next Step Towards Success with FactoryWorxTM Team Collaboration

Well, what now? Sitting on the fence is not going to solve any problems. They are just going to get bigger.

The fact is that the choice of the best MES solution for your manufacturing operation is easier than you think. FactoryWorx modular, scalable MES platform can rapidly transform manufacturing companies into Industry 4.0 leaders. It is recognised for its comprehensiveness and exceptional value by some of the leading brands as well as small manufacturing operations.

SEE THIS SOLUTION IN ACTION!

Want to see how it all works and what it can do for your company?

Schedule a tailored DEMO with our Expert.

WHAT IS YOUR KEY MANUFACTURING CHALLENGE?

We Have the Solution

Fully optimised production planning, visibility, control.

Measure and gain instant real-time insight into important data.

Automated, instantly measurable quality across a matrix of factors.

Instant visibility of component and product status, quantity and location.

Seamlessly integrates with major ERP and known business systems.

Industry 4.0 enabled, real time production environment visibility.

Control product progress/cost from components to despatch.

Faster, always accurate and reliable digital factory operations.

Lean starts with no down-time preventative maintenance.

Just plug in and action insights to reduce cost and your footprint.

Optimise yield on equipment and stock for maximum

Empower people to see the bigger picture, their progress and support.

START A FREE TRIAL

Test FactoryWorx Core Modules inn Your Operations

Try Before You Buy. Adopting new, advanced MES, Manufacturing Execution System, whether as a single function or entire Industry 4.0 transformation, is a major business commitment. It’s not just cost, but also potential disruptions, increased workloads and a steep learning curve. Not with FactoryWorx!

Energy Management

production Planning

OEE Reporting

Manufacturing Dashboard

See the Simulation first in a Personalised DEMO.