Production Reporting?

of operation.

drive strategic moves.

at every level.

Real-time insights and deep analytics for timely actions and agile decisions at your fingertips.

From real-time data visibility for accurate and timely responses to predictive-analytics-driven decisions and pre-emptive actions, FactoryWorxTM Production Reporting module infuses agility and effectiveness into manufacturing operations.

Introduction to FactoryWorxTM Production Reporting

FactoryWorxTM Production Reporting module is an out-of-the box visualisation and reporting system that provides manufacturing, warehousing and distribution operations with an extraordinary capacity for valuable and timely insights that drive pre-emptive actions and reliable, accurate decisions.

FactoryWorxTM Production Reporting module is a vital component of Industry 4.0 and IIoT powered FactoryWorxTM MES solution. Unlike most of manufacturing reporting systems, FactoryWorxTM Production Reporting module has a superior ability to connect, access and leverage data, giving our clients a massive competitive advantage to accelerate their operations and quality of outcomes.

FactoryWorxTM

MES ENQUIRY

Starting with automation or looking for a holistic MES Solution? Start Here.

FactoryWorxTM Production Reporting solves the biggest business challenge: How can we make more accurate decisions and respond faster.

FactoryWorx - Real Time Reporting

Real time data and reporting is the foundation of smooth manufacturing operation. It enables people in all areas to react in a timely manner to important events, take corrective or preventative action. This simultaneously saves costs and improves profit margins, by preventing downtime, costly breakdowns, producing faulty goods, and any reasons that can stop or disrupt production.

Through its sensor-enhanced capabilities, FactoryWorxTM Production Reporting module delivers meaningful real-time and predictive insights to all areas of operations. This means full visibility of all physical and digital factors, enabling, planning and responsiveness to the enterprise-wide and customer-supply-chain interdependencies.

FactoryWorx - Stand-Alone Reporting Capability

At FactoryWorx we recognise that manufacturers are often restricted in how they can utilise their expensive specialist equipment. Any interference or modification of equipment can wave the all-important warranty. FactoryWorxTM Production Reporting software enables us to drop in stand-alone IoT sensors to produce reports directly from any equipment in your factory, lab or warehouse – without interfering with the equipment in any way.

FactoryWorxTM Production Reporting answers the big question: How can we adopt a digitized reporting system without having to invest in additional equipment?

FactoryWorx - Perfect Reports Using What You’ve Got

FactoryWorxTM Production Reporting module enables you to produce reports without or with minimum cost by using equipment you already have. How?

If your manufacturing facility, lab or warehouse already has one or more of the following devices, you already have the capability of generating perfect reports in FactoryWorx software. FactoryWorx will safely connect your special equipment via additional stand-alone IoT Sensors.

IoT Printers

Smart Scales

Check Weighers

IoT Historian

FactoryWorx - The Future of Production Reporting is Here

Our software will help you create great reports that provide clarity, insights and even predictive analytics for best performance. But unlike other Production Reporting software, FactoryWorxTM Production Reporting has the capability of building an innovative Omni-Visible Live Intelligence Hub.

The future of Production Reporting is as much about the quality of Data, best Analytics as it is about the speed and omni-presence of insights. having information available just on the desktop, or on the production line screen, or even just” on the mobile device, is no longer enough.

To address the requirement for agility and almost pervasive visibility of data in manufacturing, FactoryWorxTM Production Reporting leverages emerging technologies that enable operators, to see live data and be alerted to issues in different areas of production instantly.

This helps reduce the cost of labour and ultimately of manufacturing and is particularly valuable in advanced, AI-driven manufacturing environments. And this is the future for manufacturing and distribution.

FactoryWorxTM Production Reporting Platform

| Count and Measure | Analyse, Visualise and Report | Drive Results |

|---|---|---|

| Use Your Existing Equipment: - IoT Printers - Smart Scales - Check Weighers - IoT Historian "But we also want to get data from other equipment!" - FactoryWorx will safely connect your special equipment via additional Stand-alone IoT Sensors | FactoryWorxTM Production Reporting: Access Reports on your KPIs and get Alerts on issues from anywhere via: - TV Screens - Mobile Devices (using FactoryWorx Mobile App] - Smart Glasses - Other devices – e.g. wearables | Drive Results: - OEE - Quality - Efficiency -Team Performance - Continuous Improvement |

FactoryWorxTM Reporting Helps Drive Efficiency, Productivity and Customer Satisfaction

FactoryWorxTM Production Reporting is designed with focus on measuring and achieving KPIs and providing people concerned with production and operations critical information that supports these KPIs.

While FactoryWorxTM Reporting software is ready to plug and play without the need for customisation, it offers endless, intuitive options to users to present reports in the way that best suits teams, individuals and projects.

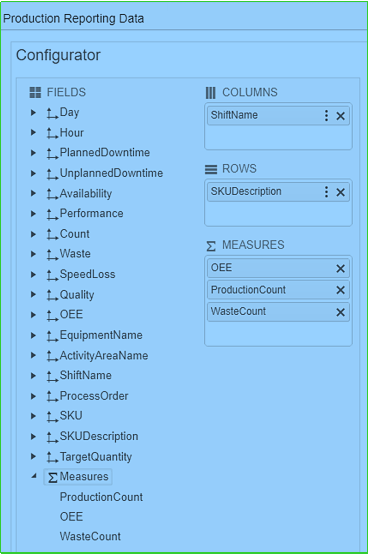

FactoryWorxTM Configurator is a data mining feature which allows to report production data across more than 20 main fields and their combinations.

BUSINESS OUTCOMES YOU WANT

Get FactoryWorxTM Production Reporting

Measure everything that matters to know how to improve.

Real-time reporting for instant response to reduce cost of waste.

Mine data to clearly see the future & make accurate decisions.

Slam OEE costs witth predictive Asset Mgt & Maintenance.

Lower the cost of Quality by reducing waste.

Optimise cost of labour with better scheduling & training.

Our Features

FactoryWorxTM Production Reporting Overview

What FactoryWorxTM Module Name offers, how is it different and why it should matter to you.

Functionality and Benefits of FactoryWorxTM Production Reporting

Explore the functionalities and their extensive Module includes a range of solutions relating to.

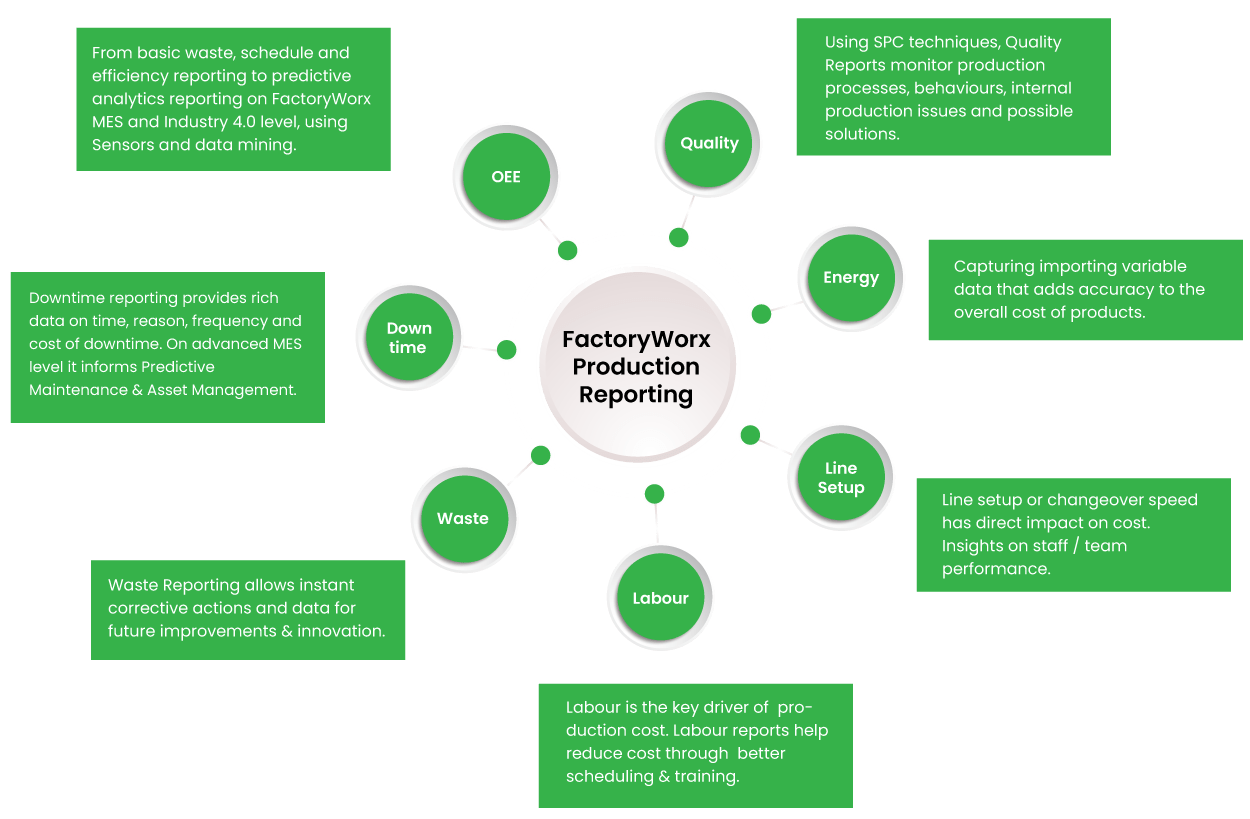

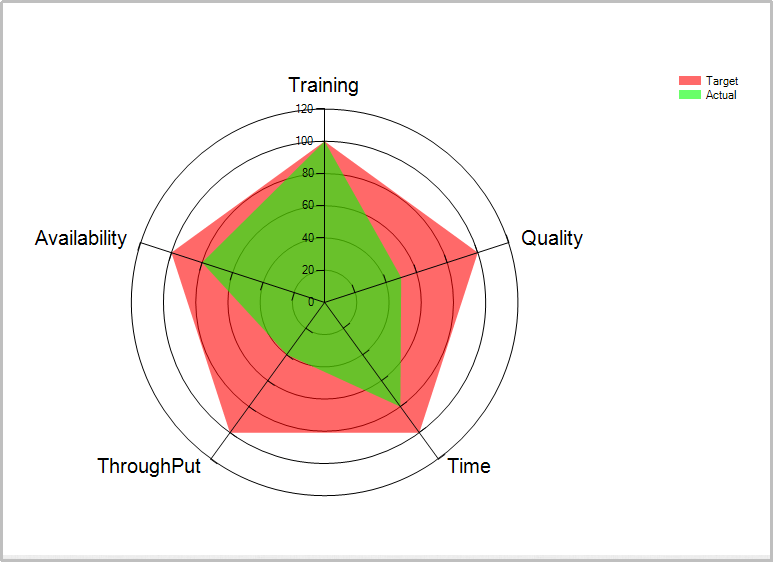

FactoryWorxTM OEE Reporting enables to monitor and analyse equipment performance data which has the major impact of business performance.

On the basic level, provides waste, schedule and efficiency reporting. On the FactoryWorx MES and Industry 4.0 level, OEE Reporting provides predictive analytics reports, using Sensors and data mining.

- OEE availability

- OEE performance

- OEE cost of maintenance

- Understand and manage equipment performance with planning based on data.

- Manage equipment utilisation to extend the life of expensive assets.

- Allocate the right people to special equipment to protect assets, reduce cost of repairs and maximise yield from equipment.

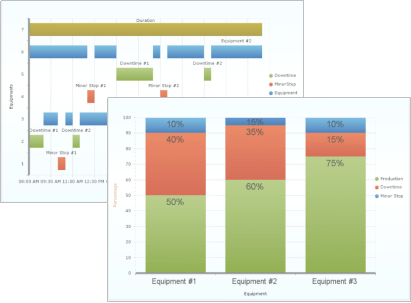

Downtime is the major cause of lost productivity, increased waste and production and product costs. If unchecked, it can cause a decline in profitability, revenue and irreparable brand damage.

FactoryWorxTM Downtime Reporting is an essential management tool that on the basic level provides instant insights on time, reason, frequency and cost of downtime. On advanced MES level it informs Predictive Maintenance and Asset Management.

- Major and minor stoppage reporting

- Speed loss reporting

- First up fault reporting

- Manual reason and action input

- Downtime Analysis and Tracking – Root Cause Analysis (RCA), i.e. 5 WHY’s are provided by Operators for future improvement.

- Manual & Automated Downtime Recording:

- Manual recording – allowing operators to enter downtime events directly in the system either when they occur or more often before the end of the shift.

- Automated recording – by direct connection to the primary packaging machine / line printer. With automatic recording the running/stop/no count signal is taken from the PLC via OPC or based on printer count. The start and stop times are therefore precise. If the PLC can give fault codes these are also captured. Operators review the list of automatically captured downtime events and update the events with downtime reasons but of course they cannot change the duration.

- FactoryWorxTMStandardised Event Downtime Classifications:

- Downtime events are classified to enables fast responses, learning and future improvements.

- Breakdowns– equipment failures technical reasons related to the equipment and process (Operator Input)

- Unplanned stops – e.g. material shortages, man-power shortages

- Planned stops – e.g. planned maintenance, changeovers, set-up

- Speed Loss – when the line isn’t producing to standard rate

- Operational– when the proper procedures have not been followed

- Minor Stops – e.machine stops that do not impact production of primary producing machine

- Equipment Reliability – Fault codes logged and reported from machine.

- FactoryWorxTMDowntime Reporting Module – enables granular reporting for deep analytics.

- Events can be investigated by machine, line, department, shift, downtime reason, downtime category and product.

- Calculates relevant KPIs, e.g. MTBF/ MTTR / MTTA

- Downtime visualised on dashboards with optional ability to raise alarms via email/SMS.

- Customer satisfaction and retention through consistent quality and delivery.

- Reduced cost of materials and waste of faulty products by eliminating faults and defects.

- Reduced cost of labour with automated quality monitoring.

- Optimised processes leveraging data and trends that lead to innovation.

FactoryWorxTM Waste Reporting captures and analyses manufacturing waste and scrap in real time to reduce and prevent losses.

- Waste detection

- Real-time reporting

- Waste analysis and reporting

- Real time waste detection and reporting.

- Real time corrective actions to reduce and eliminate losses.

- Data analysis for future process improvements and innovation

FactoryWorxTM Labour Reporting – with labour being the major driver of variable production costs, this module offers visibility of issues and inefficiencies and help reduce labour cost through better scheduling, supervision & training.

- Labour hours tracking

- Real-time performance tracking

- Tracking labour in context of OEE

- Optimise the cost of labour with better scheduling.

- Minimise downtime caused by operator behaviour or performance.

- Plan efficient training, rewards to build skilled dedicated workforce.

- Integrates with ERP to inform HR function

Line setup or changeover speed and efficacy has direct impact on cost. It provides Insights on staff / team performance and informs better staff scheduling and skilling requirements.

- Labour tracking

- Production tracking

- Provides learning into employees’ response time and quality of setup.

- Enables better future staff scheduling.

- Enables more efficient training scheduling that directly drives performance improvement.

FactoryWorxTM Quality Reporting provides real-time visibility and checks of quality issues during production, to ensure faults and defects are detected and addressed instantly for minimum waste.

Using SPC techniques, Quality Reports monitor production processes, behaviours, internal production issues and provide possible solutions.

- Quality reporting

- SPC Analysis

- Visualisation and Alarms.

- Enables instant insights into production faults – detected from machines and Master Data.

- Reduces cost of quality – with early detection and faster response to faults.

- Minimises waste with early detection of faults.

- Enables product traceability in production and through the supply chain, improving customer satisfaction.

FactoryWorxTM Energy Reporting is critical in monitoring and managing costs of energy consumption as one of the major drivers of production costs.

The FactoryWorxTM Energy Reporting module provides real time visibility and analysis of energy costs and helps identify opportunities for improvement initiatives. Capturing this analysis of important cost driver provides deeper insight into the overall cost of products.

EMS (Energy Management System)

- Automatic energy monitoring

- Energy Auditing

- EMS (Energy Management System)

- Greater accuracy of cost of products.

- Reduce cost of energy consumption with Predictive Planning of Energy Usage.

- Reduce cost of energy with predictive energy buying.

- Meeting compliance requirements for energy efficiency.

- Prevent penalties for excessive use of energy.

- Reduce overall cost of manufacturing.

- Ability to make brand claims for “greener” or carbon-neutral production and products.RELATED SOLUTIONS

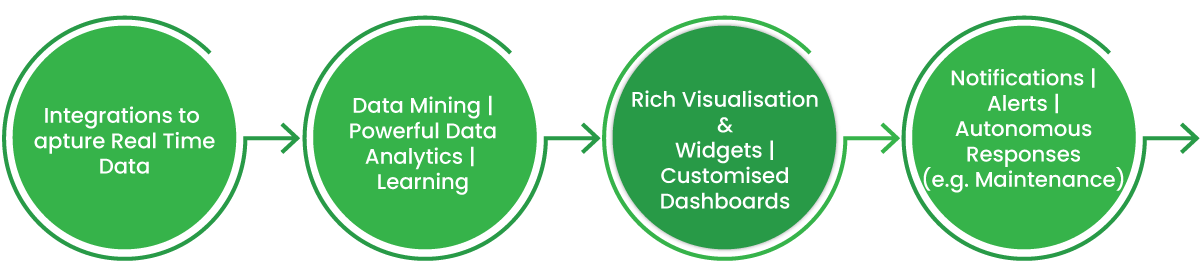

The Broader Process of FactoryWorxTM Production Reporting

Nothing in production exists or operates in isolation. Best Production Reporting systems generate intelligent and reliable reports based on connected, timely and accurate data. While FactoryWorxTM Production Reporting focuses on presenting and visualising information, the quality of this information is part of a Process.

What Makes A Good Production Report

To get the most of Production Reporting it is important to check whether the reports meet certain intuitive criteria:

- Are generated in a timely manner.

- Present comprehensive and timely information.

- Have logical and meaningful flow of information.

- Are presented in the correct format for a user.

- Are flexible enough to adjust to all the requirements that are made by the user

To deliver useful, automated production reports, leading production reporting software, such as FactoryWorxTM Production Reporting, in addition to basic charting, SPC and real-time data, has some advanced capabilities:

- Advanced charting

- Data mining

- Lean/SixSigma Tools

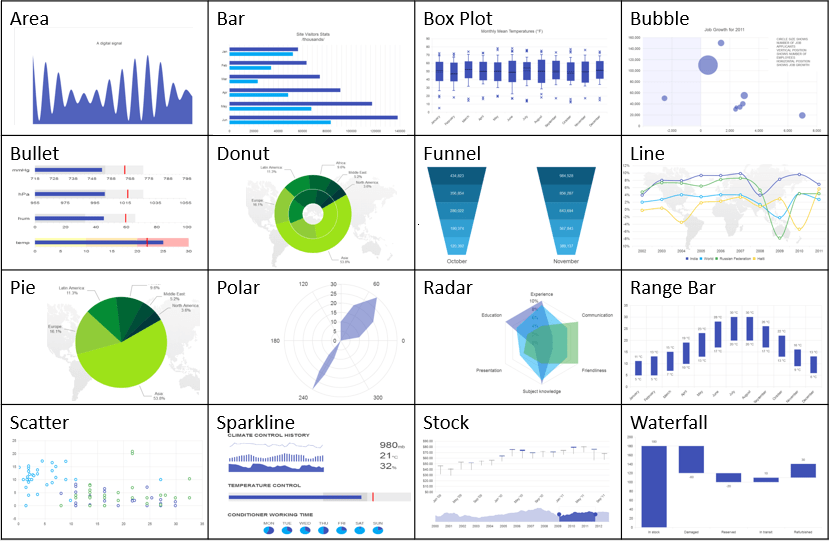

FactoryWorxTM Advanced Charting - Reporting for Impact

It’s no secret that people learn and absorb information in many different ways. While with the advance of digital and social media culture, people are becoming increasingly visual learners, images also make the most impact. Yet, there are still many ways that visual data can convey messages more effectively to different people: linear, 2- or 3-dimensional; by colour, or by what we are trying to achieve, and what motivates us.

FactoryWorxTM Production Reporting, software has an exceptional breadth of visualisation widgets and advanced graphics and visualisations to assist people in better understanding and responding to data in front of them. This enables manufacturing operations to generate reports for biggest impact on individual, team / crew, supervisory or C-suite level.

Making an Impact - Different Strokes for Different Folks

The same information, when presented from different angles, has the power to re-position the issue and its impact on the KPIs. FactoryWorx software enables people to automatically change report views.

Motivational Power of Reports

Seeing their KPIs plotted next to actual results can put a rocket under teams or individuals to try harder, prioritise better, or even just ask: why?

Notifications & Alerts

While Notifications, Alerts and Autonomous Responses are not strictly part of Production Reporting, timely notifications and alerts are related technologies that enhance the impact of reports by actually prompting people to look and perform certain tasks, e.g. Autonomous Maintenance).

FactoryWorxTM Data Mining - Reporting for Future Success

FactoryWorx Data Mining & Analytics capability allows users to configure reports using more than 20 factors to gain insights for real-time action and strategic decisions using FactoryWorx integrations including IIoT-enabled devices to achieve KPIs.

Data Mining ability comes from extensive Integrations to Capture Real Time Data – having real-time data available and enhanced with alarms and notifications, not only enables prompts corrective actions but also feeds data analytics to drive better future decisions and opportunities.

FactoryWorxTM Lean/SixSigma Tools – Reporting for Manufacturing Excellence and Leadership

Every module of FactoryWorxTM MES is equipped with access to Master Data Management and, even on the most basic level, can leverages IIoT devices to capture and leverage data for improvement. FactoryWorx’ clients have an option to deploy the full FactoryWorxTM Continuous Improvement platform or selected, critical lean tools. Data Analytics provided trends and insights to drive innovation in product and process design including supply chain innovation.

SEE THIS SOLUTION IN ACTION!

Want to see how it all works and what it can do for your company?

Schedule a tailored DEMO with our Expert.

Deploy FactoryWorxTM Production Reporting at Your Pace

The best aspect of this exceptional manufacturing solution is its flexibility. While some companies are ready to go full throttle into full Industry 4.0 transformation, and beyond; adopting FactoryWorxTM Production Reporting one functionality at a time, is a very viable option. Each of these functionalities is an independent mini-MES Module that enables implementing automation and new efficiencies where they are most needed.

If you choose to get a DEMO to see FactoryWorxTM Production Management in action, our expert will show you the best way to address your most challenging or annoying manufacturing issues.

WHAT IS YOUR KEY MANUFACTURING CHALLENGE?

We Have the Solution

Fully optimised production planning, visibility, control.

Measure and gain instant real-time insight into important data.

Automated, instantly measurable quality across a matrix of factors.

Instant visibility of component and product status, quantity and location.

Seamlessly integrates with major ERP and known business systems.

Industry 4.0 enabled, real time production environment visibility.

Control product progress/cost from components to despatch.

Faster, always accurate and reliable digital factory operations.

Lean starts with no down-time preventative maintenance.

Just plug in and action insights to reduce cost and your footprint.

Optimise yield on equipment and stock for maximum

Empower people to see the bigger picture, their progress and support.

FREE TRIAL. TRY BEFORE YOU BUY.

Test Our Key MES Modules Live in Your Factory

Adopting an advanced MES solution, whether as a single function or entire Industry 4.0 transformation, is a commitment. The difference with FactoryWorx is that our plug and play solutions minimise the usual disruptions, without adding massive workloads and learning curve.

- Energy Management

- Production Planning

- OEE Reporting

- Manufacturing Dashboard

Take the Next Step Towards Manufacturing Excellence

Well, what now? Sitting on the fence is not going to solve any problems. They are just going to get bigger.

Choosing the best MES solution for your manufacturing operation is easier than you think. FactoryWorx modular, scalable MES platform can rapidly transform manufacturing your company into an Industry 4.0 leader. Scalable for growth and offering exceptional value, FactoryWorx is the number one choice for some of the leading brands as well as small manufacturing operations.