Maintenance Solution?

down-time.

maintenance.

production assets.

Maximize Business Results with Smarter Maintenance and Asset Performance.

When every hour of downtime can translate into thousands of dollars in lost productivity and revenue, investing in an advanced CMMS, such as FactoryWorxTM Maintenance & Asset Management is an obvious answer to ensuring efficient manufacturing and customer satisfaction.

What is FactoryWorxTM Maintenance and Asset Management?

FactoryWorxTM Maintenance and Asset Management is an IIoT driven solution with advanced capability to rapidly collect and analyse data from a vast range of equipment and instantly deliver important insights. Our solution helps manufacturers to significantly reduce production costs, and drive improvement in efficiency, quality and customer satisfaction.

With exceptional integration, analytics and reporting capabilities, FactoryWorxTM Maintenance Management module enables manufacturing companies to reduce or eliminate the major production cost driver: downtime associated with equipment performance.

FactoryWorxTM

MES ENQUIRY

Starting with automation or looking for a holistic MES Solution? Start Here.

LEVERAGE THE COMBINED POWER OF INSIGHTS AND FORESIGHT

FactoryWorxTM Maintenance & Asset Management - Essential Solutions

FactoryWorxTM Maintenance Management module provides comprehensive functionality to ensure smooth, efficient and effective running of production with insights that benefit enterprise-wide decisions and projects.

FactoryWorxTM Inventory Management is a key area of Maintenance Management. Inventory has a direct impact on availability of assets and uninterrupted running of production. It can also become a major cost centre for manufacturing if unchecked.

FactoryWorxTM Inventory Management in context of Maintenance focuses on management of spare parts, tools and equipment required for the maintenance of enterprise-wide assets involved in product creation and distribution. FactoryWorx automation and digitisation of the Inventory and Purchasing function enables highly accurate, real-time tracking and control of inventory stocks.

Some parts are high cost – cannot keep too many spares. With Predictive Maintenance inventory can be managed for optimised visibility, availability and cost.

Functionality:

- Automated parts restock (Min/Max stock levels)

- Supplier Database and Pricing

- Purchase Orders and Reservations

- Inventory management and optimisation.

- Predictive Maintenance inventory

It is about having the right skills to ensure efficiency – tracking who did the job, how long it took them and have Work Instructions (digital) available instantly to ensure people can do the job quickly and easily – right the first time.

Can create and store documents online – for easy access. Browse the Digital Library or Product Manuals for instant access and information.

FactoryWorxTM Labour Management refers to managing, monitoring and scheduling people directly involved in the maintenance process.

Functionality:

- Tracking and reporting:

- Labour cost

- Individual productivity

- Skill level

- Integration with Business Software – HR – to plan training

- Labour scheduling

- Digital Work Instructions

FactoryWorxTM Asset Management organises your assets into a logical family tree structure for easy access to all asset data. It provides insights on Maintenance Activities, History, Logs, Spare Parts, Documents, Movements, etc. It also includes information on spare part suppliers, delivery lead times, pricing and more.

FactoryWorxTM Asset Management tracks and digitally documents your assets’ complete history, showing usage, breakdowns, and maintenance and repair details. Analytics and reporting functionality then provides management insights to make accurate decisions about future scheduling and utilisation of the assets to ensure maximum optimisation and ROI.

Importantly, FactoryWorxTM Asset Management is not just for the factory floor production assets. It should be integrated in all critical facilities where products are developed, tested and handled. This includes:

- Labs

- Smart Devices

- Warehouse Equipment

- Logistics- broader company assets.

Functionality:

- Asset utilisation monitoring

- Asset performance (health) monitoring

- Vibration monitoring

- Condition monitoring

- Cost analysis associated with equipment, e.g. i.e. break even to decide on replacement

- Predictive Asset Management

- Maintenance Planning

Creating Work Orders and Maintenance Requests has never been easier, faster or more effective. FactoryWorxTM Work Order Management makes it easy to create, complete and record work. Automatic tracking and Notifications ensure timely actions and enable you to achieve and exceed your KPIs.

Create Work Requests for Efficiency and Compliance:

Easily design work requests and orders by entering or selecting from the standard lists: tasks to be performed, parts, trade/person, permits, safety notes. The function will automatically record repair time and downtime. With the ERP integration you can generate WO and requests directly from Master Data and ensure accuracy with automatic updates.

Importantly, include tasks, activities and triggers from the Digital Documentation Library to ensure the mar

Automate Work Order Scheduling:

Schedule maintenance work orders using set time, meter or event-based triggers to fit in your workflows and production strategy.

Preventative Maintenance

Schedule Preventative Maintenance Work Orders, using Predictive Asset Analytics to be automatically carried out based on either Time based and/or Usage based frequencies.

Functionality:

- Work orders creation, execution and tracking

- Maintenance scheduling automation

- Work Order Scheduling for Predictive Maintenance

- Mobile App for Work Orders on the move

- Work order reporting

FactoryWorxTM Maintenance Reporting functionality provides real-time visibility and standardised reporting on all aspects of maintenance. It provides a side-by-side view of actual and targets. It also enables easy generation of customisable reports on specific KPIs for every level and function across the enterprise.

Maintenance Reporting is invaluable to monitoring and meeting production and management objectives.

Functionality:

- Asset reporting: break downs, cost of repairs

- Maintenance reporting: labour cost, efficiency

- Inventory reporting

Every module of FactoryWorxTM MES suite fully integrates with all ERP solutions as well as other IT systems within the organisation. The ERP integration provides real-time access to Master Data, enabling Work Orders creation, parts requisitions, and connecting labour hours and asset performance data with the company’s overall financial accounting.

Functionality:

- ERP integration

- Master Data Integration

- Work Orders creation

- Reporting

FactoryWorxTM Document Management is about standardising Maintenance Resources and process. It provides a standard platform that keeps all equipment data, including barcodes, available centrally in cloud. All maintenance related information is always accurate and up to date and easily accessible via Mobile technology – anywhere, any time.

FactoryWorxTM Document Management features an interactive resource, Process Mapper. It makes it easy to create custom built instructions for your specific processes and machines. These instructions or Guides, designed using Process Mapper, become a Trouble Shooter for each event. They are available in your Digital Library for operators to easily access, follow and check all process steps.

This addresses the common problem for organisations: Knowledge capture and availability to the entire Team. It enables any operator to perform a required maintenance activity irrespective of their skill level or whether they are new or casual staff. The digital Document Management function provides an instant knowledge boost – where there is limited experience of business process knowledge. Ensuring speed and continuity of operations.

FactoryWorxTM Document Management functionality is essential in the age of workforce outsourcing and solves the 2nd biggest issue of downtime: lack of skilled staff to do even basic maintenance.

Digital Work Instructions, Product and Repair Manuals directly integrate with FactoryWorxTM Production Management module.

Functionality:

- Document Management Library

- Process Mapper

- Trouble Shooter – Guides

- Paperless – Digital Work Instructions

FactoryWorxTM Maintenance Management comes with a Mobile App. It reflects how people work and naturally interact with each other today. In manufacturing in particular, everyone is on the move and important actions and decisions need to be made instantly. It allows you and your team to do your job anywhere, anytime.

Operators can easily create a maintenance request at a push of a button. You will instantly receive email confirmation. Easy to use, it accelerates and improves effectiveness of communication. It eliminates skill and language barriers and provides clarity and efficiency of communicating issues.

Just take a photo or quick video of the problem, mark up on your screen what needs to be addressed and send to a maintenance specialist who may be in another location.

FactoryWorxTM Mobile App automatically updates asset’s history and Work Orders.

Functionality:

- Full functionality of the FactoryWorxTMMaintenance Management module

- Work Order creation

- Maintenance Request creation

When FactoryWorxTM Maintenance Management is implemented as part of FactoryWorxTM Industry 4.0, with some AI capability, you can start to leverage the benefits of Predictive Asset Management. This functionality allows companies to manage asset utilisation, repairs and lifecycle for maximum yield and financial returns.

FactoryWorxTM Predictive Asset Management functionality informs management decisions with relentless accuracy about when and what the best options are for maintenance and scheduling of a particular production asset. Real time monitoring, combined with advanced data analytics provide insights that prevent equipment failures and downtime.

This not only minimises the cost of repairs but also improves asset’s longevity and ROI.

Take the guesswork and “unplanned” out of your manufacturing operations with FactoryWorxTM Predictive Asset Management. Gain full control of machines, tools, auxiliary equipment and labour performance.

CREATE MORE VALUE ON THE BOTTOM LINE

Your Benefits with FactoryWorxTM Maintenance Management

Implementing FactoryWorxTM Maintenance Management system has a direct impact on every aspect of your manufacturing and business performance.

Feature-rich System

Drive excellence in Maintenance and Asset management.

Easy to Deploy

FactoryWorx is an IIoT enabled, plug-and-play software.

Easy to Use

Intuitive, intelligent tool with cloud based Help and Resource Library as well as human support .

Holistic MES Solution

Maintenance and Asset Management is part of a comprehensive modular FactoryWorx MES platform.

Reduced cost of repairs and maintenance.

Eliminated downtime from equipment failure.

Improved maintenance efficiency using Process Mapper (Trouble Shooter).

Increased equipment availability.

Optimised asset utilisation.

Increased ROI on assets / equipment

Reduced inventory and purchasing cost.

Accurate performance and historical asset maintenance data.

Automated, reliable Job Tracking.

Optimised labour training and utilisation with digital work instructions.

Accurate asset and labour performance reporting and management.

Optimised inventory cost with predictive inventory management.

Book a DEMO today and see how FactoryWorx can help you.

With so many possibilities, our Expert will help you find the right solution for you.

SUPPORTING YOUR MANUFACTURING STRATEGY

FactoryWorxTM Goals-Based Maintenance

What Is A Goals-Based Approach to Maintenance?

The main purpose of the goal-based approach to maintenance is to set quantifiable goals to reduce the impact of a maintenance problem. The approach provides a structure for automation to achieve the desired metric. Then you can program your Maintenance to achieve this Goal using FactoryWorxTM Maintenance Management software.

FactoryWorxTM Goals-Based Maintenance Solution

FactoryWorxTM Maintenance Management module, through its systems and IIoT integration capabilities, plays a key role in manufacturing strategy. From collecting data to saving costs of inventory, labour and transportation, to predictive analytics that drive strategic decisions on the C-suite level.

Importantly, FactoryWorxTM Maintenance Management software provides visual linking and mapping of the process to all relevant parts of the operation. It provides total enterprise-wide visibility of, e.g. waste. This may be of major interest not just to production management but also to Quality Assurance and Continuous Improvement functions. Often, these functions operate in silos, further reinforced by having these goals maintained in different IT systems to production.

FactoryWorxTM Maintenance Management digitally links these diverse, cross-functional Goals so they can reinforce each other. Real time visibility enables people in different parts of the organisation to see how other Goals impact their own work and vice versa.

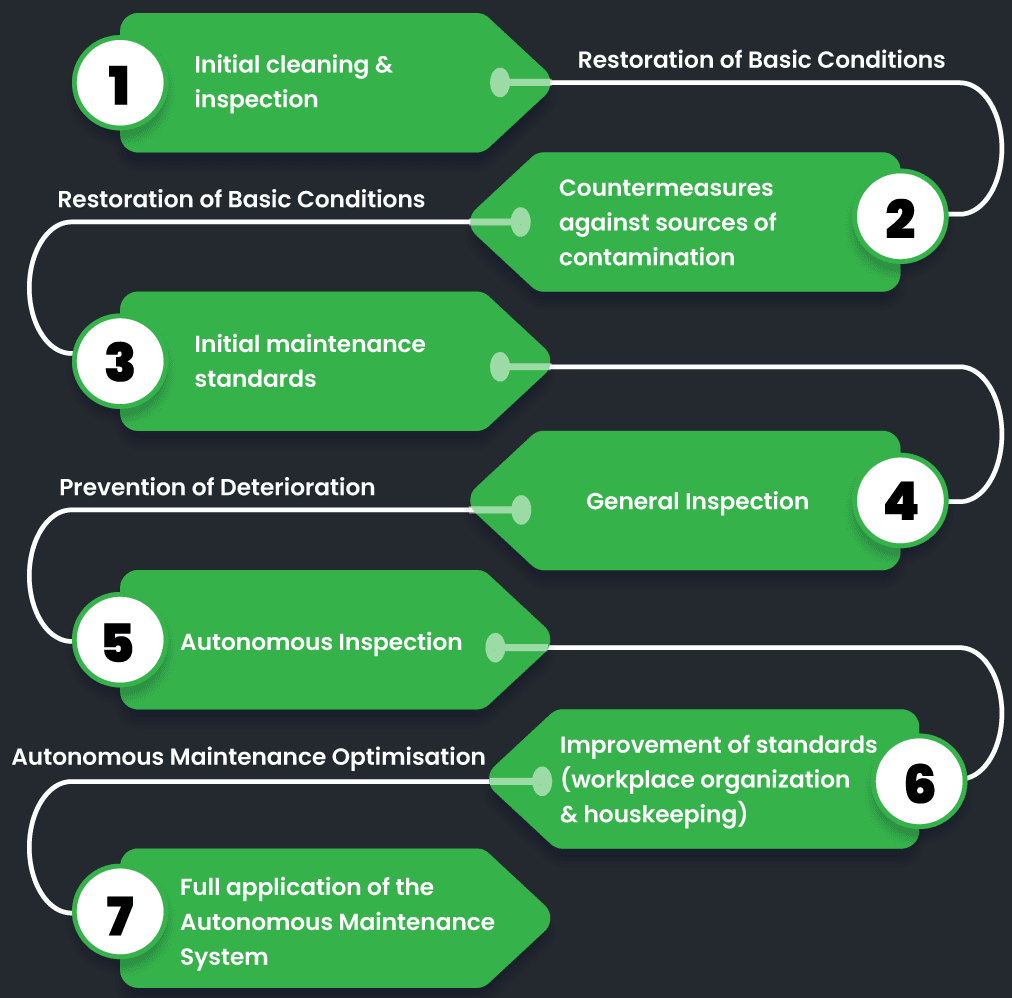

THE FUTURE OF MAINTENANCE IS HERE

Embrace the future with FactoryWorxTM Autonomous Maintenance

What is Autonomous Maintenance?

Autonomous Maintenance or Total Productive Maintenance (TPM) is referred to maintenance carried out independently by the operators rather than by dedicated maintenance technicians. It enables efficient preventative and improvement works.

Unlike traditional maintenance programs where the operators run the machines until they break down or become due for routine maintenance by the maintenance department, autonomous maintenance has the operators performing the simpler (and safe) maintenance routines such as lubrication, bolt tightening, cleaning and also inspection and monitoring.

Easily Transition to FactoryWorxTM Autonomous Maintenance

The standard, in-built features and functionality of FactoryWorxTM Maintenance Management software provides a direct path to Autonomous Maintenance.

From the initial deployment it provides Standardisation of processes for better Maintenance practices – grounded in Digital Work instructions and digital Document Management. As your organisation moves towards Industry 4.0 and AI, with increased use of Predictive Analytics and digitisation, you will make rapid progress through Preventative Maintenance to Autonomous Maintenance.

At FactoryWorx we recognise that advanced technology requires more than software, machines and process. To succeed it needs people to lead, follow and be empowered. To help you achieve and fully leverage the benefits of Autonomous Maintenance, through our Partner ecosystem we can provide support in:

- Change Management

- Training and Coaching

- Culture Transformation.

Deploy FactoryWorxTM Maintenance Management on Your Terms

One of the most valued benefits of FactoryWorxTM MES modular solutions is flexibility. You can easily deploy one functionality at a time, starting with FactoryWorxTM Maintenance Management. Each Module is independent and will enable you to deploy automation and efficiencies where they are most needed.

Request a DEMO to see FactoryWorxTM Maintenance Management in action. Our expert will show you the best way to address your most challenging or annoying manufacturing issues.

DEPLOYMENT OPTIONS:

- Cloud – SaaS, Web-based

- Desktop – Mac, Windows, Linux

- Mobile – iPhone, Android, iPad

- On-Premises – Windows, Linux

PRICING OPTIONS:

- Free Trial

- Monthly Subscription

- Annual Subscription

- One-Time License

Take the Next Step Towards Success with FactoryWorxTM Maintenance & Asset Management

TAKE ONE STEP TOWARDS GREATER SUCCESS!

See this Solution in Action.

Want to see how it works and what it can do for your company?

Schedule a tailored DEMO with our Expert.

WHAT IS YOUR KEY MANUFACTURING CHALLENGE?

We Have the Solution

Fully optimised production planning, visibility, control.

Measure and gain instant real-time insight into important data.

Automated, instantly measurable quality across a matrix of factors.

Instant visibility of component and product status, quantity and location.

Seamlessly integrates with major ERP and known business systems.

Industry 4.0 enabled, real time production environment visibility.

Control product progress/cost from components to despatch.

Faster, always accurate and reliable digital factory operations.

Lean starts with no down-time preventative maintenance.

Just plug in and action insights to reduce cost and your footprint.

Optimise yield on equipment and stock for maximum

Empower people to see the bigger picture, their progress and support.

START FREE TRIAL

Test FactoryWorx Core Modules in Your Operations

Try Before You Buy. Adopting new, advanced MES, Manufacturing Execution System, whether as a single function or entire Industry 4.0 transformation, is a major business commitment. It’s not just cost, but also potential disruptions, increased workloads and a steep learning curve. Not with FactoryWorx!

Energy Management

production Planning

OEE Reporting

Manufacturing Dashboard