AI Powered MES?

business disruptions.

already in Pilot Project.

AI Powered MES

Introduction to FactoryWorxTM AI

FactoryWorxTM Artificial Intelligence (AI) Platform uses deep IIoT connectivity and Machine Learning to create new opportunities for manufacturing and distribution companies to grow and innovate with unprecedented speed and accuracy across internal operations and the entire value chain.

With the ability to capture meaningful data from every piece of equipment on the factory floor, and from broader business systems and external sources, your business can well leverage Artificial Intelligence to make better decisions to reduce costs, increase efficiency and drive innovation.

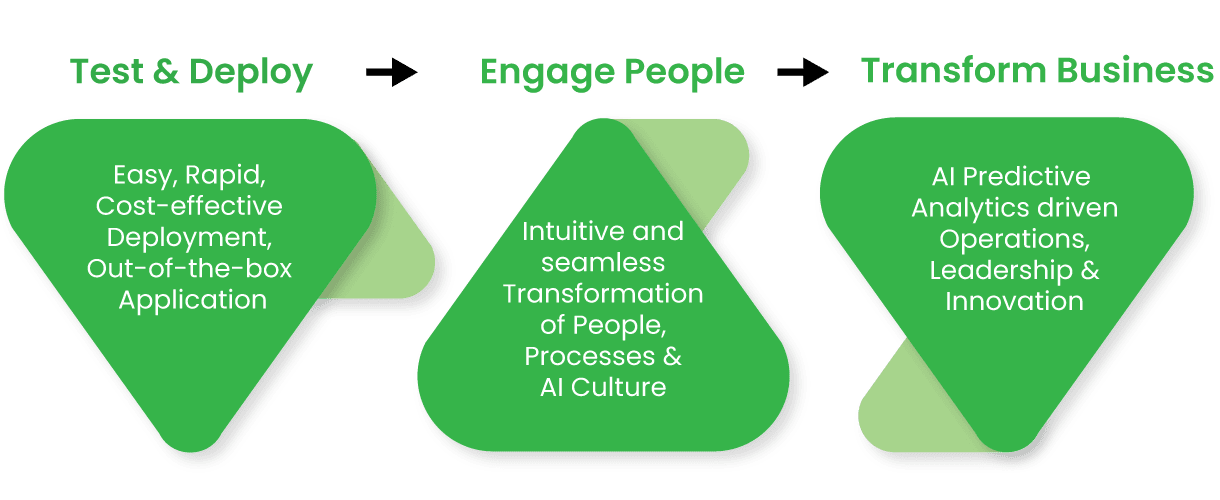

Adopting to FactoryWorxTM AI is Easier than You Think

Yet, many companies lack or think they lack the ability adopt Artificial Intelligence. FactoryWorxTM AI makes it easy.

- You need to start with a smart MES.

- FactoryWorxTMAI is easy to deploy, i.e. it won’t cause disruptions to production.

- FactoryWorxTMAI rapid deployment delivers rapid results, i.e. you can see returns in the first stage.

- You can start small withFactoryWorxTM AI Pilot Project.

- FactoryWorxTMAI is an out-of-the-box application, i.e. it doesn’t require specialist programming skills.

- FactoryWorxTMAI recognises that the human factor in critical to AI success. We help you manage it.

- FactoryWorxTMAI is cost effective, i.e. you don’t need to pay for a big brand name.

FactoryWorxTM

MES ENQUIRY

Starting with automation or looking for a holistic MES Solution? Start Here.

Your FactoryWorxTM AI Adoption Process

The FactoryWorxTM AI Difference

FactoryWorxTM Artificial Intelligence (AI) Platform uses deep IIoT connectivity and Machine Learning to create new opportunities for manufacturing and distribution companies to grow and innovate with unprecedented speed and accuracy across internal operations and the entire value chain.

With the ability to capture meaningful data from every piece of equipment on the factory floor, and from broader business systems and external sources, your business can leverage FactoryWorxTM AI is to make better decisions to reduce costs, increase efficiency and drive innovation.

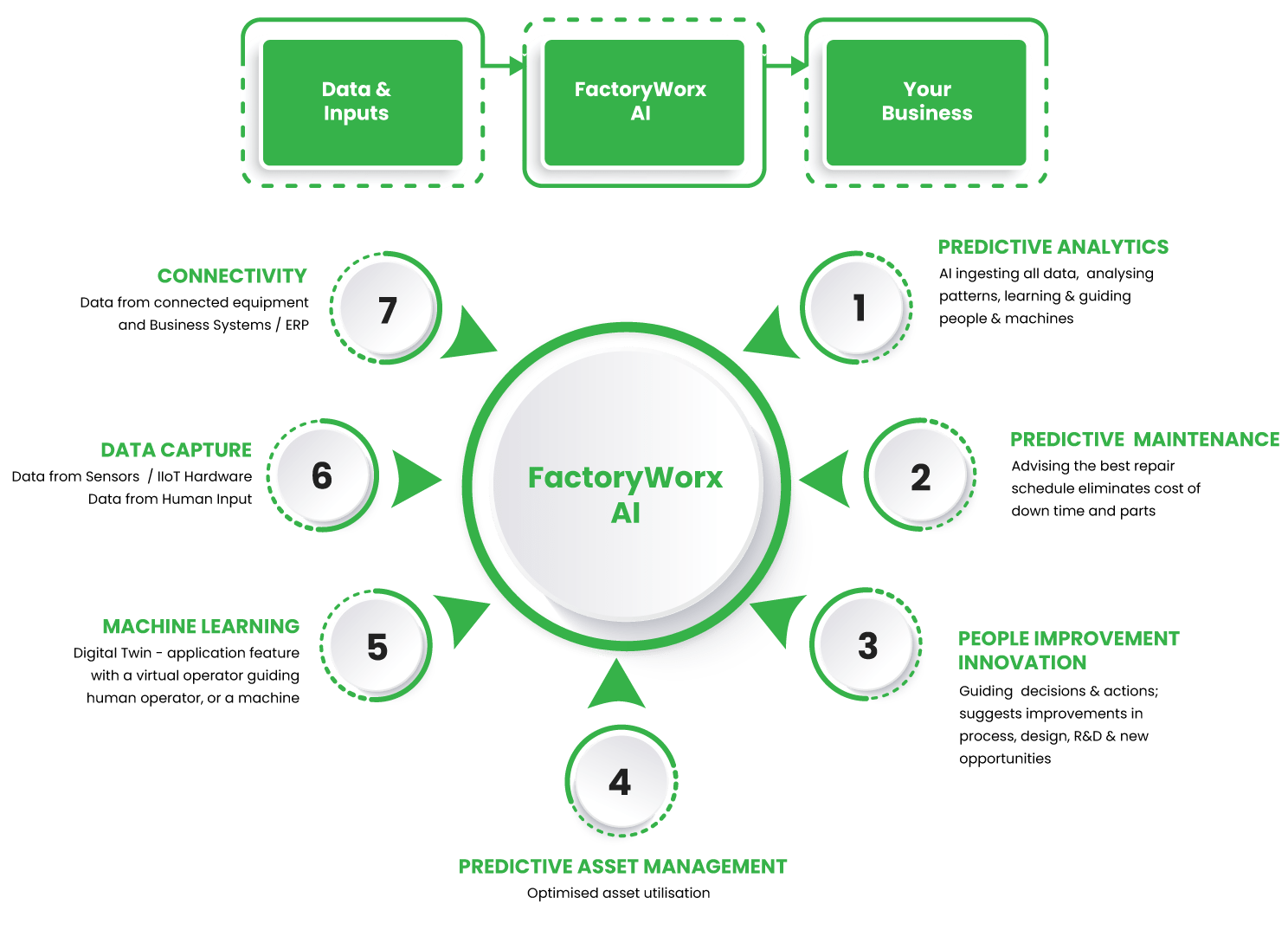

- Predictive analysis inform people on what might happen, when, with what degree of certainty and impact.

- Pre-emptive and corrective actions optimise asset utilisation, maintenance, labour and inventory, and prevent downtime and breakdowns.

- Show improvement opportunities in any part of operations by recognising patterns, leading to improvement in efficiencies, design, logistics and people performance.

- Improve people management using technologies such as Chatbots to guide projects and personal performance.

FactoryWorxTM AI Optimises Every Aspect of Operations

FactoryWorxTM AI is designed to leverage your existing data capabilities, deep machine learning to enable the FactoryWorxTM Digital Twin to learn and guide business on timely and pre-emptive actions and future decisions.

WHAT IS YOUR KEY MANUFACTURING CHALLENGE?

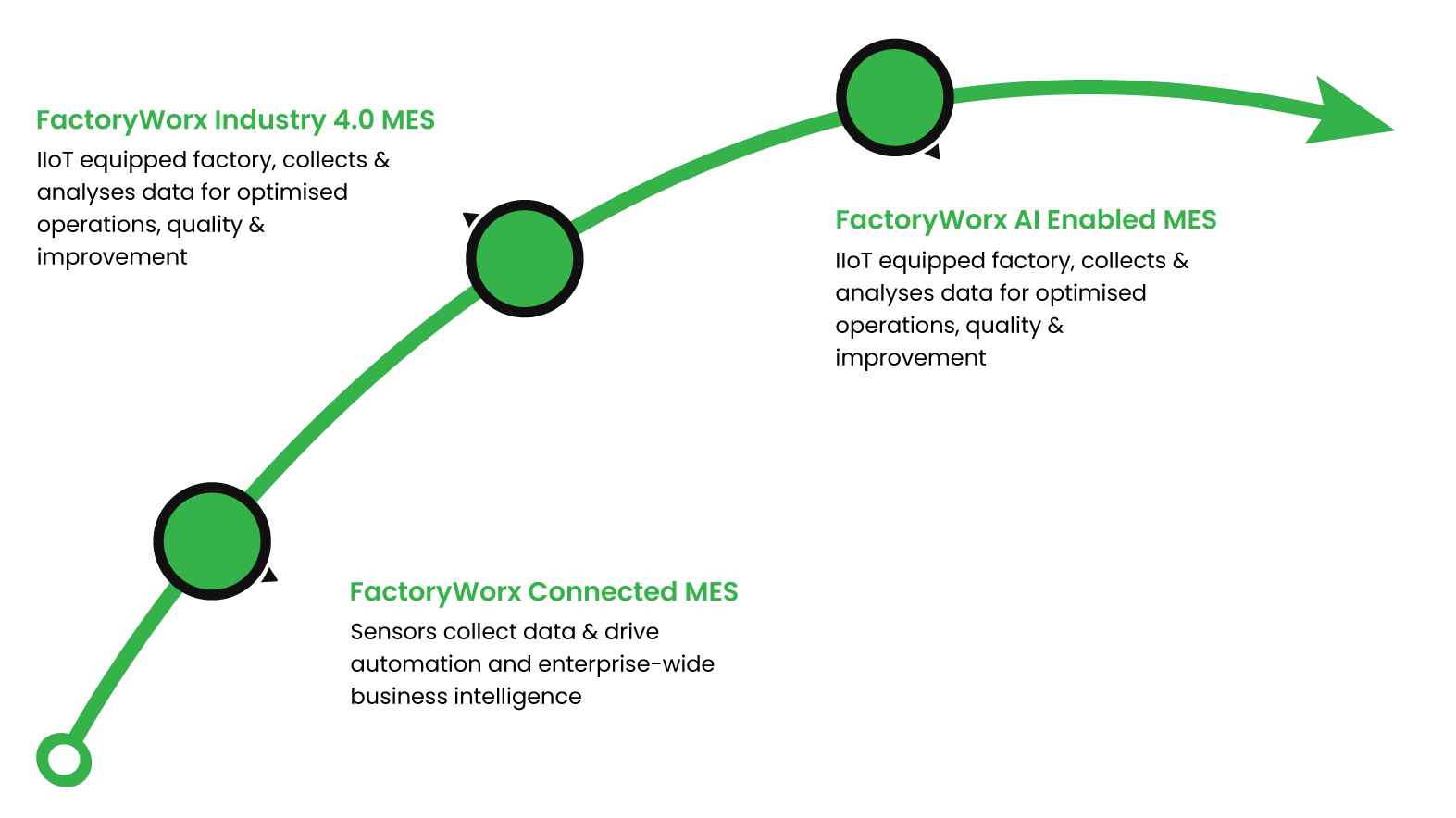

Deploy FactoryWorxTM AI at Your Pace

Today adopting AI is not an optional choice. It is a matter of competitive urgency. The next five years will see operations without AI left behind. The window of opportunity is still open. With FactoryWorxTM AI you have a choice: to go full throttle to a full AI powered Industry 4.0 transformation or take a staged roll out.

With either option adopting FactoryWorxTM AI starts with a Project Pilot and follows logical steps to fully embed and leverage AI development, learning and the necessary organisational transformation.

If you are already using FactoryWorxTM MES, your operations are already connected. You already have the infrastructure and are collecting vital data. You can start with AI and move fast. It’s just a question of scaling the process.

FactoryWorx Path to AI Powered Operations

Explore the Functionality and Benefits of FactoryWorxTM AI

FactoryWorxTM AI platform delivers cost savings, revenue opportunities and excellence across all aspects of Manufacturing and Distribution operations and throughout the Supply Chain.

FactoryWorxTM Predictive Analytics underpin an intelligent factory through constant learning, remembering and analysing large volume of connected date to guide truly informed, forward-looking actions and decisions in business.

- Efficient defects detection improves quality

- Predictive maintenance reduces downtime.

- Real-time scheduling in response to changes in the supply chain.

- Consistent quality standards.

- Reduced cost of product customization.

FactoryWorxTM Predictive Maintenance is the most widely requested AI capability, which also accounts for 29% of all manufacturing AI use cases globally.

- Reduced cost of repairs

- Reduced cost of downtime

- Improved machine performance

- Improved production efficiency

Heavy asset industries, such as Manufacturing and Mining rely on FactoryWorxTM Predictive Asset Management. AI driven monitoring, learning and predictive guidance enables our clients to optimise asset maintenance and utilisation by advising timely corrective actions.

- Optimise asset ROI

- Guiding predictive maintenance

- Eliminate the cost of routine checking

- Prevent break downs and asset damage

- Extend the life of assets

- Prompts informed decisions

FactoryWorxTM Advanced Process Control uses AI to enable our clients to monitor, control and optimize their processes and use of assets by guiding decision at all levels and pre-emptive actions.

- Maximise operational performance.

- Maximise asset performance.

- Increase production yield.

- Generate operational savings, e.g. energy

FactoryWorxTM Transportation management (TMS) provides advanced view of materials used in production enabling automated replenishment. FactoryWorxTM TMS includes highly specialised functionalities: COR and Load Builder.

- Chain of responsibility (COR) ensures that all parties in the supply chain take responsibility for adhering to road transport laws while handling related goods.

- FactoryWorxTM Load Builder is used is manufacturing and distribution operations to automates and optimises the cost of transportation. It is increasingly used in lights-out | dark factory in conjunction with FactoryWorxTM Integrations such as Automation & Robotics, e.g. LGVs.

- Reduced cost of storage and distribution.

- Maximise lean operations.

- No out-of-stock downtimes.

- Optimised cost of stock

- Reduced or eliminated cost of labour.

- Highest levels of compliance: environment, legal and wastage

- Protects brand & business reputation

FactoryWorxTM AI delivers multiple opportunities for Predictive Operations Management through a range of functionalities related to production processes:

- Project management

- Continuous Improvement

- Innovation – R&D and Design

- More efficient Project Management – with AI driven prompts and reminders

- Reduced need for PMs or their time

- Improve employee satisfaction by automating mundane tasks

- Insights for process improvement

- Innovation insights from Big Data patterns

- Improved data distribution and Team collaboration

- Better, data-driven decisions

FactoryWorx Breaks Key Barriers to Implementing AI

- Current technologies not mature (40%)

- Workforce lacks skills to implement and manage AI (40%)

- FactoryWorxTMAI doesn’t require specialist coding

- FactoryWorxTMAI is deployed quickly

- FactoryWorxTMAI is simple to implement – operators may not even notice it’s “AI”

- FactoryWorxTMAI comes with expert change management communication (when required) to ensure transparency and institutional trust building from the start

- FactoryWorxTMAI facilitates and optimises regulatory compliance, e.g. FactoryWorxTM

See FactoryWorxTM AI In Action!

Want to see how it all works and what it can do for your company?

Schedule a tailored DEMO with our Expert.

How FactoryWorxTM AI Supports the Key Industries

FactoryWorxTM AI for Manufacturing

FactoryWorxTM Predictive Analytics functionality is the foundation of AI and its ability to deliver high ROI through cost savings, responsiveness to customer changing demands and needs, and to opportunities and creating value in the supply chain. Specifically, FactoryWorxTM AI for manufacturing is used by our clients to:

- Optimise Maintenance - FactoryWorxTM Predictive Maintenance delivers major savings in cost of planned and unplanned maintenance, reduced downtime and cost of equipment breakdowns.

- Asset management

- Optimise defect detection – reducing reliance on costly skilled engineering.

- Quality Assurance – improving quality output and reducing the cost of manual inspection.

- Optimise Assembly Line – scheduling and managing people to optimise cost of labour and performance.

- Design Optimisation – learning AI can detect patterns for improvement product design.

FactoryWorxTM AI for Building & Construction Materials

FactoryWorxTM AI enables companies with heavy assets improve product throughput and quality consistency, optimise energy consumption and maximise profit. Importantly, it reduces reliance on operators’ skills and experience. Machine intelligence can run in autonomous mode, monitoring and adjusting production inputs and performance while operators can focus on more complex tasks that add value. Importantly, your AI is learning without interruptions which leads to further improving future business outcomes.

FactoryWorxTM AI for Mining

Condition monitoring and prevention has never been more important to the mining sector than today. FactoryWorxTM Predictive Maintenance solution delivers early warning for planned or unplanned but predicted requirement of equipment maintenance, resulting in less downtime and reduced cost of FactoryWorxTM Predictive Asset Management solution delivers early warning and recommends pre-emptive actions to accurately plan the best response to future events, such as blast noise, air quality or vibrations.

FactoryWorxTM AI in Logistics & Distribution

FactoryWorxTM Transportation management (TMS) provides advanced view of materials used in production enabling automated replenishment. FactoryWorxTM TMS includes highly specialised functionalities: COR and Load Builder.

Chain of responsibility (COR) ensures that all parties in the supply chain take responsibility for adhering to road transport laws while handling related goods.

FactoryWorxTM Load Builderois used is manufacturing and distribution operations to automates and optimises the cost of transportation. It is increasingly used in lights-out | dark factory in conjunction with FactoryWorxTM Integrations such as Automation & Robotics, e.g. LGVs

STILL THINKING ABOUT IT?

Should You Adopt FactoryWorxTM AI

Ask yourself these questions:

- Is my industry highly competitive and we need to optimise every aspect of business? Is our industry prone to revenue volatility with changing market demands?

- Is saving costs a major performance driver?

- Is production changing from long runs to small batches with many options?

- Are regulation, compliance and inspections on the rise?

- Is ensuring learning and adaptability on the factory floor hard to manage?

- Are we still managing production capacity and supply chain semi-manually?

- Do we leverage available data to make more informed decisions?

IS YOUR CURRENT MES READY FOR AI?

Explore FactoryWorx Advanced MES Solutions

Fully optimised production planning, visibility, control.

Measure and gain instant real-time insight into important data.

Automated, instantly measurable quality across a matrix of factors.

Instant visibility of component and product status, quantity and location.

Seamlessly integrates with major ERP and known business systems.

Industry 4.0 enabled, real time production environment visibility.

Control product progress/cost from components to despatch.

Faster, always accurate and reliable digital factory operations.

Lean starts with no down-time preventative maintenance.

Just plug in and action insights to reduce cost and your footprint.

Optimise yield on equipment and stock for maximum

Empower people to see the bigger picture, their progress and support.

THINK BIG. START SMALL.

Ready For Your FactoryWorxTM Pilot Project?

Adopting FactoryWorxTM AI is easy, rapid and generates fast returns on the bottom line!

See the Simulation first in a Personalised DEMO.

Take the Next Step Towards Manufacturing Excellence

Well, what now? Sitting on the fence is not going to solve any problems. They are just going to get bigger.

The fact is that the choice of the best MES solution for your manufacturing operation is easier than you think. FactoryWorx modular, scalable MES platform can rapidly transform manufacturing companies into Industry 4.0 leaders. It is recognised for its comprehensiveness and exceptional value by some of the leading brands as well as small manufacturing operations.