Paperless?

Instant data access.

data accuracy.

customer & compliance.

Faster, always accurate and reliable digital factory operations.

Paperless manufacturing not just about replacing paper documents with digital and saving trees. It’s primarily about outcomes, achieved through capture and leverage of data to drive better business decisions and ultimately performance. Smart platforms such as FactoryWorxTM Paperless facilitate and accelerate digital manufacturing transformation.

What is Paperless Manufacturing?

The concept of Paperless Manufacturing was first discussed by visionary business leaders nearly 50 ago but only now that it is being made possible with the growth of IIoT-driven digitisation. And there is a narrow window of opportunity to make it your competitive advantage.

Paperless Manufacturing is holistic business process designed to help manufacturers automate the answers to increasingly more challenges and decisions the face on daily basis.

It is achieved by digitising all operations, that integrates the shopfloor with enterprise-wide decision-making in real-time. Paperless systems effectively connect machines, processes, systems and people as intelligent networks. Advanced solutions such as FactoryWorxTM Paperless also connect and autonomously control the entire value chain through to end customer.

- FactoryWorxTM Logistics Transportation Management (TMS)

- FactoryWorxTM Chain of Responsibility (COR)

- FactoryWorxTM Load Builder

Paperless is about:

- Data

- Outcomes

- Efficiency

- Cost

- Quality

- Customer Satisfaction

FactoryWorxTM

MES ENQUIRY

Starting with automation or looking for a holistic MES Solution? Start Here.

Introduction to FactoryWorxTM Paperless Solution

FactoryWorxTM Paperless solution enables companies to create a digital environment where reliable and fully integrated workflows that are instantly visible and available when and where needed. The processes you will be able to design and build with the FactoryWorxTM Paperless are outcome-focused flows, based on dynamic data and analytics that reflect your operations.

FactoryWorxTM Paperless solution puts rapid data analytics and information at your fingertips, anywhere, anytime to make better decisions and take timely actions. This adds exceptional flexibility and efficiency to your operations.

Our software platform comes with essential functionalities, best practice process, professional support, and a myriad of valuable MES, ERP, and IIoT integrations that make your digital, paperless transformation with FactoryWorxTM Paperless comprehensive, fast, easy and cost-effective.

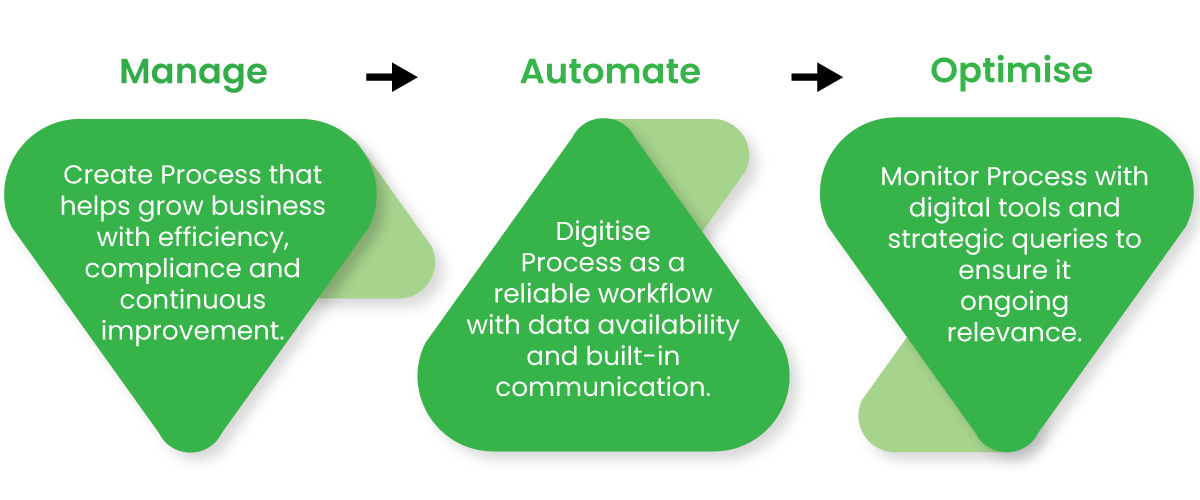

There are three elements to digital transformation in manufacturing and FactoryWorxTM Paperless seamlessly links them:

Controlling the Shop Floor

Connecting the Business

Unlocking People Potential

FactoryWorxTM Paperless - Cloud

Paperless concept is about Cloud. To be omnipresent and universally available, data must be connected and live. Leading solutions such as FactoryWorxTM Paperless connect not just information that is already digitally available. It uses its IIoT connectivity to also connect physical side of operations to always see the full picture of operations.

With FactoryWorxTM Paperless you will be able to collect data that can be measured or counted from all equipment, using both sensors and your other intelligent machines, such as scales, checkers, etc.

IT’S ALL ABOUT OUTCOMES

Digital Transformation with FactoryWorxTM Paperless

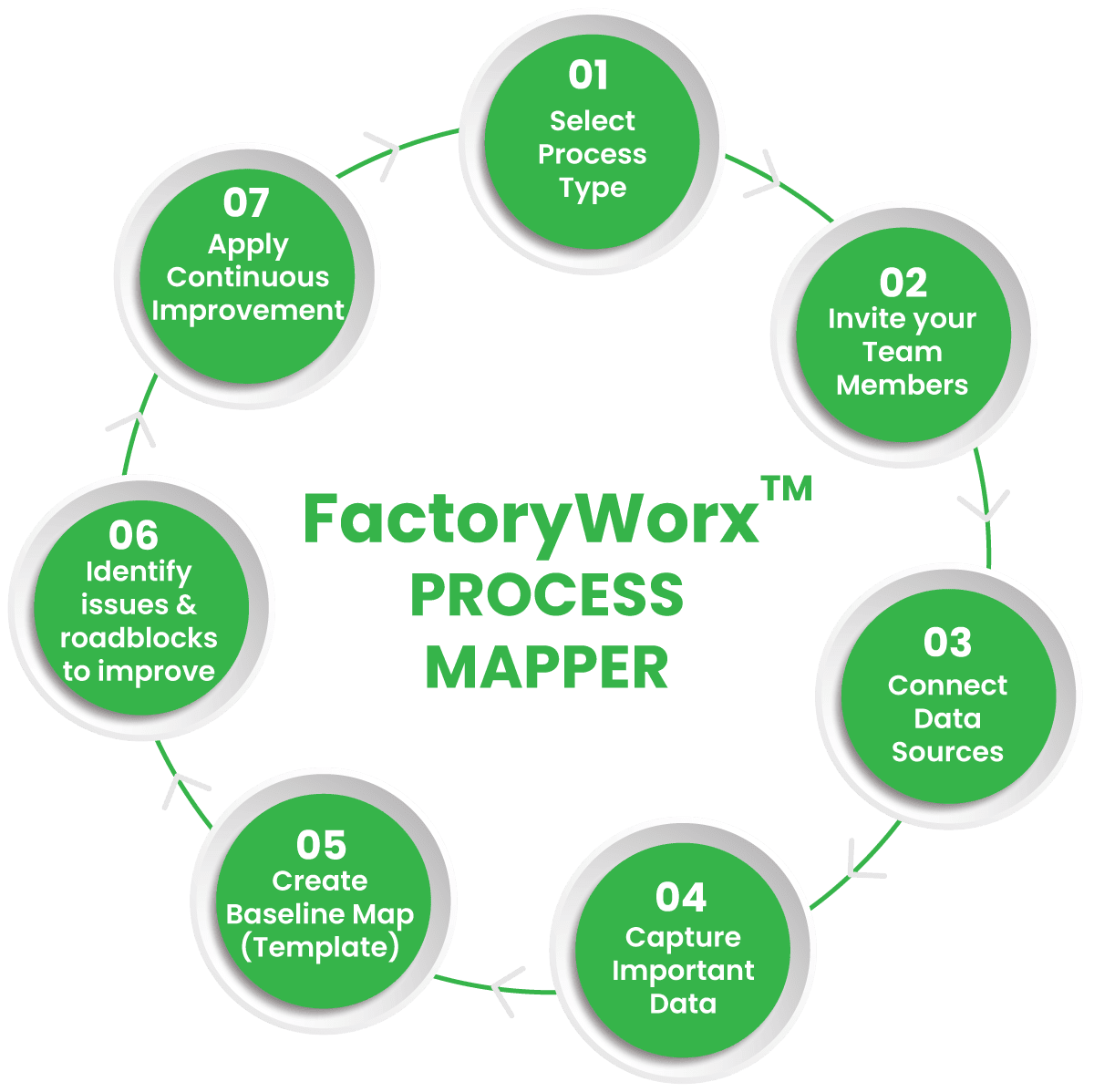

FactoryWorxTM Paperless software automates the process of creating and delivering consistent quality to customers. At the core of the transformation is FactoryWorxTM Process Mapper.

The Strategic Path to Paperless

Smart companies use the strategic process when going paperless to rethink not just their winning processes but also the company culture to ensure people at all levels are aligned with the inevitable change.

Manage

FactoryWorxTM From Builder enables you to plan, map and integrate all business processes with new, easy to use tools.

Plan

Use our strategic process and tap into our Partner resources to focus on Outcomes you want.

Map

Use our Process Mapper to start your digital process with a framework and easy tools.

Lead

Guide the Team to develop and apply non-negotiable principles for standards and improvement.

Integrations

Using FactoryWorxTM Integrations, easily connect data from all internal and essential external sources.

Automate

FactoryWorxTM Form Builder enables you to start automation where it is most needed. Just identify your most valuable or most wasteful processes and you are ready to go – no programming required.

Eliminate paper and errors and give people access anywhere.

Automate repetitive, time consuming work with workflows and robotic process automation (RPA).

Generate documents with pre-built templates and enable secure e-signatures and authorisations.

Optimize

Optimise your processes with automation, leveraging the connected data for ongoing improvement. FactoryWorxTM modular MES platform makes it easy to connect the dots of your digital operations by automating the three critical tasks of paperless.

Use automation to monitor processes to remove roadblocks.

Use dashboards to visualise what can be improved.

Use easy design tools to change process flows automatically.

3 EASY STEPS TO PAPERLESS TRANSFORMATION

FactoryWorxTM Paperless – Process Design

FactoryWorxTM Paperless is an outcome-driven solution. In order to map effective business processes, first you need to select the broad approach based on what you want to achieve. Then, let FactoryWorxTM Paperless 3-step Process take you there.

Step 1: Process Mapping

What is FactoryWorxTM Process Mapper?

When selecting your Paperless solution make sure it ticks the following criteria:

- Responsive– Using lessons from previous experience, issues and bottlenecks are factored in.

- Planned– Mapping will be based on and as an essential part of the business plan.

- Customer-Focused– Using customer satisfaction as the guide for mapping your steps.

FactoryWorxTM Process Mapper is a tool used to Manage, Automate, and Optimize your paperless processes without any need for programming. It is an out-of-the-box, intuitive application. It will enable you to:

- Design the entire process flow

- Attach forms to the Flow

- Attach emails, alerts, electronic signatures

- Build Process Flow graphically

- Deploy to devices – make it available to anyone in production / operations

Design Any Process with FactoryWorxTM Process Mapper

FactoryWorxTM Paperless process mapping is about effective communication to help people get better outcomes. Different process Maps are used to visualise different types of activities.

A visual display of a process tracking the flow of material, information, or service through all its steps.

A workflow diagram is a visual representation of a business process (or workflow), usually done through a flowchart.

Distinct boxes used to symbolize a very abbreviated form of a process for quick understanding.

This map represents a standard process level that involves Supplier collaborations, Input, Process, Output, Customer (SIPOC)

Lean technique that analyses and helps design step-by-step work process to deliver value from start to finish until it reaches customer.

Showcases present state and upcoming state processes to highlight areas for enhancement

Using documents as inputs and outputs in the process.

Explains each step of the process.

Splits out the sub-process responsibilities in the process.

The benefits of using FactoryWorxTM Process Mapper

- Simple and Pre-built forms

- Convenient to use

- Responsive

- Easy Customization

- Real-Time Testing

- Great for Surveys

- Boundless themes and templates

- Lead generation

Step 2: Your Digital Documentation with Form Builder

What is FactoryWorxTM Form Builder?

FactoryWorxTM From Builder is a perfect tool to provide availability of up-to-date digital information for faster decisions, responsiveness and resources utilisation. It is designed for simplicity of use for anyone to create customized forms and documents, share on any device, and get required information in real time to support your operations.

FactoryWorxTM Paperless provides you with an ability to create forms that anyone can create and fill in, using pre-built templates and instantly access analytics with our integrations. Forms are seamlessly integrated with the workflows, data and analytics.

Create critical business documents like contracts, work orders, and invoices, instantly. And, importantly, with FX Form Builder, consistently. No coding, no extra 3rd party apps required. Integrates with all your data sources and business systems, ERP, MES and CRM. Precision and rapid execution every time.

Just 3 Reasons to Use FactoryWorxTM Form Builder:

Access any data instantly with powerful integrations to give your documents a compelling voice.

Create any document fast with pre-built templates for latest compliance, in any format you require.

Automate and streamline authorisations with e-signatures and secure delivery.

YOUR ADDED ADVANTAGE

FactoryWorxTM Robotic Process Automation (RPA)

With FactoryWorxTM Paperless you can leverage our AI capability to add trained bots to further accelerate your paperless automation. Again, no coding is required, just easy drag-and-drop intuitive interface. Gain a powerful solution to streamline and manage your processes by leveraging big data from both structured and unstructured data sources.

Benefits

- Flawless Accuracy

- Cost Transparency

- Rapid ROI

Step 3: Workflows Optimised for Success

Digitising and Automating Workflows with FactoryWorxTM Paperless

Simplified and intuitive workflows are easier to learn and apply consistently. FactoryWorxTM Paperless adds an extra dimension of intelligent integration to automate your workflows as well their continuous improvement. By connecting source of data with documents and communication channels, your workflows are always current, accurate and drive success of people and organisation. This is the unique ability of FactoryWorxTM Paperless to add the essential layer of intelligence to your business processes.

Benefits of Workflow Automation:

- Quick, intuitive design

- Self-driving process from creation to approval

- Enhanced cross-channel collaboration

- Cloud-led access from anywhere

- Bot-friendly for ultimate efficiency

Leverage the Benefits of FactoryWorxTM Paperless

Implementing the FactoryWorxTM Paperless system has a direct impact on every aspect of the organization’s performance. While the value of a paperless system is common knowledge, FactoryWorxTM Paperless brings magnified benefits through its IIoT connectivity, integrations, and the scalability of FactoryWorxTM advanced MES, Continuous Improvement and Industry 4.0 platforms.

Deploy FactoryWorxTM Paperless Management on Your Terms

One of the most valued benefits of FactoryWorxTM MES Modular solutions is flexibility. If you are not ready to go full throttle into Industry 4.0 transformation, you can easily adopt the complete FactoryWorxTM PAPERLESS or roll it out one functionality at a time. Both options are equally viable depending on your situation and needs.

Each Module and its logical functionalities is an independent mini-MES Module that enables deploying automation and efficiencies where they are most needed.

Request a DEMO to see FactoryWorxTM PAPERLESS in action and our expert will show you the best way to address your most challenging manufacturing issues.

DEPLOYMENT OPTIONS:

- Cloud – SaaS, Web-based

- Desktop – Mac, Windows, Linux

- Mobile – iPhone, Android, iPad

- On-Premises – Windows, Linux

PRICING OPTIONS:

- Free Trial

- Monthly Subscription

- Annual Subscription

- One-Time License

Find out what FactoryWorxTM Paperless can do for YOU!

Want to see how it works and what it can do for your company?

Schedule a tailored DEMO with our Expert.

WHAT IS YOUR KEY MANUFACTURING CHALLENGE?

We Have the Solution

Fully optimised production planning, visibility, control.

Measure and gain instant real-time insight into important data.

Automated, instantly measurable quality across a matrix of factors.

Instant visibility of component and product status, quantity and location.

Seamlessly integrates with major ERP and known business systems.

Industry 4.0 enabled, real time production environment visibility.

Control product progress/cost from components to despatch.

Faster, always accurate and reliable digital factory operations.

Lean starts with no down-time preventative maintenance.

Just plug in and action insights to reduce cost and your footprint.

Optimise yield on equipment and stock for maximum

Empower people to see the bigger picture, their progress and support.

START A FREE TRIAL

Test FactoryWorx Core Modules in Your Operations

Try Before You Buy. Adopting new, advanced MES, Manufacturing Execution System, whether as a single function or entire Industry 4.0 transformation, is a major business commitment. It’s not just cost, but also potential disruptions, increased workloads and a steep learning curve. Not with FactoryWorx!

Energy Management

production Planning

OEE Reporting

Manufacturing Dashboard

See the Simulation first in a Personalised DEMO.